When designing high-performance electronic devices, alumina (Al2O3) has become the first choice for ceramic printed circuit boards (PCBs) due to its excellent thermoelectric properties. But not all alumina is the same! In this article, we will explore the difference between 96% alumina and 99% alumina.

What is alumina? Why is it used in ceramic PCBs?

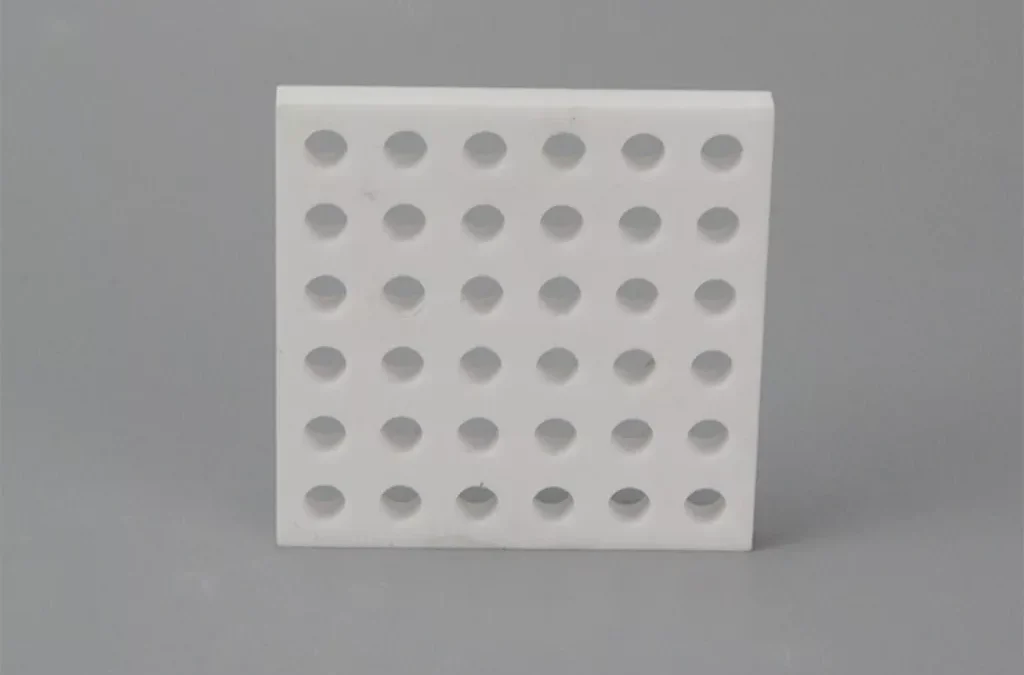

Alumina ceramic substrates are mainly composed of white amorphous powder, commonly known as aluminum oxide or simply Al2O3. Density: 3.9-4.0 g/cm3, melting point: 2050℃, boiling point: 2980℃, insoluble in water, and show excellent performance in various applications.

Ordinary alumina ceramics are divided into 99%, 95%, 90%, 96%, 85%, and sometimes 80% or 75% alumina according to their Al2O3 content. 99% alumina refers to aluminum oxide with a purity of 99.5% or 99.8%, which is white or ivory in color and has excellent properties such as high wear resistance, acid and alkali corrosion resistance, and excellent performance at high temperatures (1600-1700 degrees Celsius).

In addition, alumina also has good chemical stability, high electrical insulation, strong adsorption capacity and wear resistance. Therefore, it is widely used in various applications, including lamps, electronic devices, sandblasting nozzles, automotive parts and wear-resistant components.

On the other hand, 96% alumina is slightly lower in purity than 99% alumina, but it is still economical while providing good thermal conductivity and insulation properties.

96% Alumina VS 99% Alumina

96% alumina is composed of 96% pure aluminum oxide and 4% other trace elements. Due to its balanced performance and cost-effectiveness, this type is widely used in various electronic applications. Here are some of its typical properties.

1. Good thermal conductivity can effectively dissipate heat from high-power components.

2. Good dielectric strength ensures reliable insulation between conductive lines on PCBs.

3. The rugged nature contributes to the overall mechanical integrity of the ceramic PCB.

4. Compared to its higher purity counterparts, 96% alumina is more cost-effective, making it an attractive choice for cost-sensitive projects.

99% alumina is a premium variant with an impressive 99% purity level accompanied by minimal impurities.

It is suitable for the most demanding scenarios requiring superior mechanical, electrical, thermal or corrosion resistance. Here are the main advantages of 99% alumina:

1. Due to its superior thermal conductivity than 96% alumina, 99% alumina ensures uniform heating of the material as a whole, which helps to dissipate heat efficiently. This feature is particularly important for equipment that generates a lot of heat during operation.

2. The inherent properties of the material enable simple and compact design, resulting in smaller equipment. This advantage is particularly critical for applications with space constraints.

3. 99% alumina has a flat and smooth surface, which improves its mechanical strength. This ensures that the material remains strong and not easily damaged during use.

4. Due to its high purity, 99% alumina exhibits excellent resistance to acid and alkali corrosion, ensuring the longevity and durability of the material in corrosive environments.

5. The higher purity of 99% alumina leads to better accuracy and stability in various electrical performance characteristics. This feature is particularly beneficial for high-precision electronic applications that require consistent and reliable performance.

How to choose the right material for our ceramic PCB?

1. Project requirements:

Clearly define your project requirements. Evaluate the power consumption requirements, voltage requirements, and temperature conditions of the electronic components in the project. If excellent thermal conductivity and high dielectric strength are required, 99% alumina may be a better choice. For low to medium power requirements, 96% alumina can provide stable and cost-effective performance.

2. Budget constraints:

Budget plays a vital role in material selection. While 99% alumina offers excellent performance, it is also more expensive than 96% alumina. When choosing a material, balance the project requirements and available budget to ensure value for money.

3. Equipment design:

If your equipment involves multiple functional areas with different material performance requirements, segmenting the PCB into areas with different purity of alumina is a viable option. Use 99% alumina in areas that require high performance, and 96% alumina in other areas with lower performance requirements.

If you have any needs about industrial ceramic materials, please feel free to contact us at any time 0086-17702411651