The performance and application advantages of zirconia ceramics

The performance and application advantages of zirconia ceramicsFlange Pure ZrO2 is white, yellow or gray when it contains impurities, and generally contains HfO2, which is not easy to separate. The world's proven zirconium resources are about 19 million tons, and...

The purpose and use method of ceramic flange disc

The purpose and use method of ceramic flange discFlange is a mechanical structure that realizes the axial (length direction) connection of two objects. Flanges are also called flange flanges or flanges. Flange is a part that connects between shaft and shaft and is...

Why does alumina ceramics turn yellow in color?

Why does alumina ceramics turn yellow in color?Alumina ceramics is a ceramic material with Al2O3 as the main crystalline phase. Due to its high melting point, high hardness, heat resistance, corrosion resistance, and electrical insulation characteristics, it can be...

How to test the hardness of advanced ceramics

How to test the hardness of advanced ceramicsCeramic materials have made great progress as an important inorganic non-metallic material. In particular, structural ceramics are widely used in metallurgy, chemical industry, aerospace and other fields due to their high...

Precision ceramics are more and more widely used in semiconductor equipment

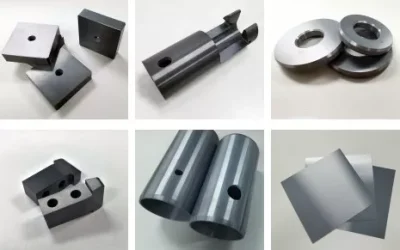

Precision ceramics are more and more widely used in semiconductor equipmentAs a key component of semiconductor production equipment, the R&D and production of precision ceramic components directly affects the development of the semiconductor equipment...

Introduction of ceramic injection molding process

Introduction of ceramic injection molding processThe ceramic injection molding process mainly includes four processes: feeding, injection molding, degreasing and sintering.1. Selection and optimization of powder As the main material for injection molding, the most...

Application of silicon nitride ceramics in industry

Application of silicon nitride ceramics in industrySilicon nitride ceramics are advanced engineering ceramics with high strength, fracture toughness, hardness, wear resistance and good chemical and thermal stability. Silicon nitride is a polycrystalline composite...

Advantages of Industrial Zirconia Ceramic Pistons

Advantages of Industrial Zirconia Ceramic PistonsZirconia ceramic materials can be processed into various types of mechanical parts, because they have a series of advantages such as wear resistance and high temperature resistance. Processed zirconia ceramic...

Properties and applications of thermally conductive ceramic gaskets

Properties and applications of thermally conductive ceramic gasketsThermally conductive ceramic gasket is a material with high thermal conductivity. It is mainly made of alumina (alumina content as high as 95%) or zirconia. It has a pure white appearance and a hard...

Advantages of Industrial Zirconia Ceramic Pistons

Advantages of Industrial Zirconia Ceramic PistonsZirconia ceramic materials can be processed into various types of mechanical parts, because they have a series of advantages such as wear resistance and high temperature resistance. Processed zirconia ceramic...

Silicon Carbide and Alumina Ceramics

Comparing the properties of silicon carbide ceramics and alumina ceramicsAlthough alumina ceramics are the most widely used ceramic materials, silicon carbide ceramics are increasingly popular in high-end applications due to their excellent properties.Silicon carbide...

Microporous Ceramics and Advanced Ceramics

What is the difference between microporous ceramics and advanced ceramics?Microporous ceramics refer to ceramic bodies that contain a large number of open or closed tiny pores inside or on the surface of the ceramic, and their pore sizes are generally micron or...

Contact

*Your contact won’t be shared with 3rd party.

Shenyang Vhandy Technology Co., Ltd.

Room 401, D11 Block (Shenyang International Software Park), Shenyang, Liaoning, China

Phone/WeChat/WhatsApp

Tel

0086-24-31501218