Shield from Corrosion: Power of Vhandy Ceramic Coatings

Is the constant battle against corrosion causing headaches and eating away at your valuable assets? Fear not, for Vhandy Ceramics has the ultimate solution that will shield your investments from the destructive forces of corrosion. Get ready to witness the power of...

Unlock the Potential of Cutting-Edge Ceramic Solutions

Are you searching for a game-changing solution that can withstand extreme conditions, provide exceptional insulation, and deliver unparalleled performance? Look no further! Vhandy, a leader in customized ceramic innovations, is here to unlock the untapped potential in...

What is Advanced Ceramics

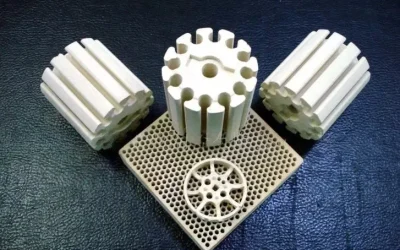

What is Advanced CeramicsAdvanced ceramics include alumina ceramic, steatite ceramic, zirconia ceramic, silicon carbide ceramic, cordierite ceramic, mullite ceramic, and others. Alumina ceramic is one of the most widely used advanced ceramics and is made from aluminum...

Production Technology of Cordierite Ceramics

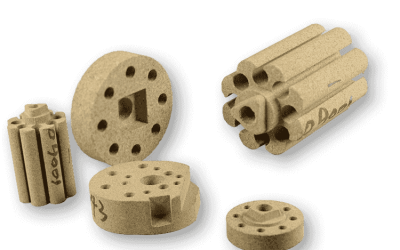

Production Technology of Cordierite CeramicsCordierite ceramics can be produced using various methods such as solid-state reaction, aqueous tape casting process, and high-temperature sintering. The aqueous tape casting process involves using polyvinylalcohol (PVA) and...

Advantages and Disadvantages of Alumina Ceramics

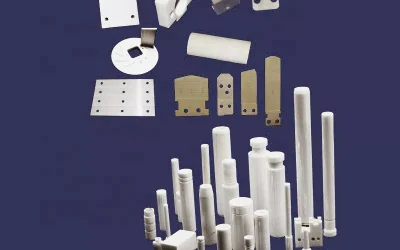

Advantages and Disadvantages of Alumina CeramicsAlumina ceramics have many advantages. They have excellent insulation, low high-frequency loss but good high-frequency insulation, heat resistance, small thermal expansion coefficient, high mechanical strength, and good...

Advantages and Disadvantages of Zirconia Ceramics

Advantages and Disadvantages of Zirconia CeramicsAs an emerging ceramic material, zirconia ceramics have the following advantages: High hardness, high strength, high toughness, wear resistance, impact resistance and fracture resistance; Low thermal conductivity, high...

Disadvantage of Cordierite Ceramics

Disadvantage of Cordierite CeramicsCordierite ceramics is a porous ceramic material with the advantages of low thermal expansion coefficient, high porosity, and high strength. It is often used as the core component of high-temperature dust removal, waste gas treatment...

Cordierite Ceramics: A New Type of Ceramic Materials

A Brief Introduction to Cordierite Ceramics: A New Type of Ceramic MaterialsCordierite ceramics are a kind of ceramic materials with cordierite (2MgO·2Al2O3·5SiO2) as the main component. Cordierite ceramics have the following advantages: Low thermal expansion...

Zirconia Ceramic: A New Type of High-Tech Ceramic

Zirconia Ceramic: A New Type of High-Tech CeramicZirconia ceramic, also known as ZrO2 ceramic (Zirconia Ceramic), is a new type of high-tech ceramic with many excellent properties and application prospects. The main features of zirconia ceramic are: High strength and...

Advantage of Alumina Ceramics

Advantage of Alumina Ceramics.Alumina ceramic is a high-performance engineering ceramic material with many advantages, such as high hardness, wear resistance, high temperature resistance, corrosion resistance, electrical insulation, etc. It is widely used in various...

What are technical ceramics?

What are technical ceramics?Technical ceramics are a type of ceramic products that are used for advanced engineering and scientific purposes. They have outstanding properties that make them suitable for various applications, such as high temperature, high pressure,...

Effect of talcum powder in alumina ceramics

Effect of talcum powder in alumina ceramicsBecause of its high mechanical strength, high hardness, wear resistance, high temperature resistance, corrosion resistance, and excellent thermal conductivity, alumina ceramics are widely used in the fields of machinery,...

Contact

*Your contact won’t be shared with 3rd party.

Shenyang Vhandy Technology Co., Ltd.

Room 401, D11 Block (Shenyang International Software Park), Shenyang, Liaoning, China

Phone/WeChat/WhatsApp

Tel

0086-24-31501218