New functional ceramic materials are a class of dielectric materials with electrical, magnetic, optical, acoustic, thermal, mechanical, chemical or biological functions. These ceramic materials have a variety of functions, including ferroelectric, piezoelectric, dielectric, pyroelectric, semiconductor, electro-optical and magnetic. They play an important role in modern high-tech fields such as electronic information, integrated circuits, mobile communications, energy technology and defense industry.

The following is a brief introduction to some new functional ceramic materials:

1. Semiconductor materials:

Semiconductor ceramics are polycrystalline ceramic materials molded using ceramic processes. Unlike polycrystalline semiconductors, semiconductor ceramics form a large number of grain boundaries during the sintering process. They are mainly used as sensitive materials, including heat-sensitive materials, voltage-sensitive materials, light-sensitive materials, gas-sensitive materials and moisture-sensitive materials.

2. Magnetic ceramic materials:

Cmainly refers to ferrite ceramics, which is a composite oxide composed of iron oxide and other iron or rare earth oxides. Ferrite has semiconductor properties, the resistivity is much higher than the general metal magnetic materials, so in the field of high-frequency and microwave technology is widely used, such as radar technology, communications technology, space technology and electronic computers.

3. High-temperature superconducting materials:

Refers to functional ceramic materials with high superconducting temperature relative to metals. In recent years, the research and application of high-temperature superconducting ceramic materials has attracted widespread attention, especially in the development of high-current applications, electronics applications and antimagnetism.

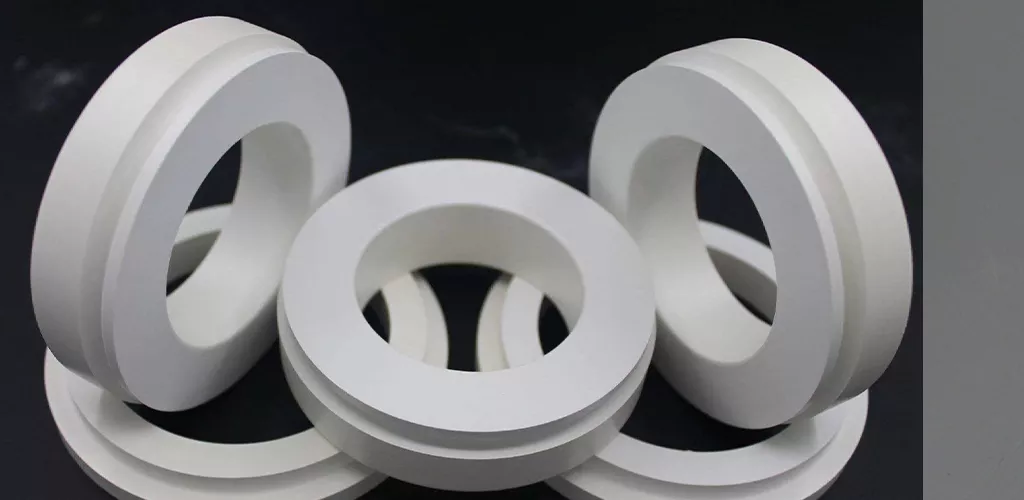

4. Insulating materials:

Insulating ceramics are mainly used in electronic equipment for mounting, fixing, supporting, protecting, insulating, isolating and connecting various radio components and devices. Insulating ceramics require high volume resistivity, low dielectric constant, low loss factor, high dielectric strength, corrosion resistance and good mechanical properties. Common insulating ceramic applications include circuit substrates, encapsulation, high frequency insulating ceramics and other areas.

5. dielectric ceramics:

Also known as dielectric ceramics, is a class of functional ceramic materials that have the ability to polarize under the action of an electric field and can maintain the electric field in the body for a long time. Dielectric ceramics have high insulation resistance, high withstand voltage, low dielectric constant, low dielectric loss, high mechanical strength and good chemical stability and other characteristics, mainly used in capacitors and microwave circuit components.

6. Nano-functional ceramics:

This is a class of new ceramic materials applied in the fields of air purification and water treatment, with antibacterial, activation, adsorption, filtration and other functions. They have the release of far-infrared rays, negative ions, photocatalytic antibacterial, deodorization, adsorption, filtration and mineralization functions.

7. piezoelectric ceramics:

Piezoelectric ceramics is a class of functional ceramic materials that can deform or generate an electric charge under an applied electric field or mechanical stress. They have a piezoelectric effect and inverse piezoelectric effect, can be converted into mechanical energy, or in turn will be converted into mechanical energy. Piezoelectric ceramics are widely used in sensors, transducers, piezoelectric ceramic motors, acoustic wave devices, electronic oscillators and other fields.

These new functional ceramic materials play an important role in various fields, promoting the development of modern science and technology and the innovation of applications. With the continuous progress of science and technology, the research and application of new functional ceramic materials will be further deepened, bringing more convenience and progress for our life and industry.

If you need ceramic products, please feel free to contact us, we will provide you with high quality customized products and professional solutions.

FAQ

Can you provide samples for me to test? How much does it cost?

We strive to provide ceramic samples that closely meet your requirements to the best of our abilities.

The samples are completely free, but you need to pay the freight.

For samples with unique shapes that require custom molds, we are open to discussing the mold cost in order to accommodate your specific needs.

We don’t know which material of ceramic we need, what should we do?

No worries! Please provide us with more details about your requirements, such as the intended use, desired properties, and any specific characteristics you're looking for.

With these information, our team can guide you in selecting the most suitable ceramic material for your needs.

We are concerned about the quality of the product we ordered.

We understand your worries and we maintain stringent quality control standards as following:

| Test Standard | Testing Dimension | Pass Rate | Standard Range |

|---|---|---|---|

| Appearance Inspection | Quantity and Severity of Defects | ≥ 97.3% | Determined by AQL standard |

| Dimensional Inspection | Size Accuracy and Consistency | ≥ 98.1% | Determined by ISO 9001 standard |

| Density Testing | Material Density | ≥ 97% | Determined by ASTM C20 standard |

| Hardness Testing | Surface Hardness | ≥ 98.2% | Determined by ISO 6508 standard |

| Flexural Strength Testing | Material Flexural Strength | ≥ 97.9% | Determined by ASTM C1161 standard |

| Thermal Shock Stability Testing | Material Thermal Shock Stability | ≥ 98.7% | Determined by ASTM C884 standard |

*Qualification standards higher than ISO standards

In addition to production line inspections, we also accept inspections from third-party organizations several times a month

While the occurrence of defects is extremely rare, it is an unavoidable possibility. If any quality issues arise, we take full responsibility and will expedite the reproduction process at cost price.

Our commitment is to ensure that our products meet the highest quality standards and promptly address any concerns to ensure customer satisfaction.

What is the processing accuracy of ceramics?

| Precision Requirement | Example | Unit |

|---|---|---|

| Surface Flatness | Ra ≤ 0.1 μm | μm |

| Dimensional Accuracy | Tolerance within tens of μm | μm |

| Aperture Precision | Diameter tolerance within a few hundred μm | μm |

| Surface Finish | Ra ≤ 0.2 μm | μm |

We maintain strict processing precision standards, ensuring that our products meet the majority of requirements using our standard manufacturing processes.

However, if you have a need for even higher precision products, please feel free to contact us.

We can discuss your specific requirements and explore customized solutions to meet your exacting standards.

What's your trade terms?

We prefer EXW, FOB and CIF as for terms.

T/T, West Union,30% deposit, 70% balance paid before delivery are greatly appreciated.

How long does your production take?

Q: What is the typical production lead time for Vhandy Ceramics?

A: The typical production lead time for Vhandy Ceramics is 15 to 20 days.

Q: Are there any situations where the actual delivery time may be longer?

A: Yes, in certain cases, such as shipping to distant countries, the actual delivery time may be extended beyond the standard range.

Q: What factors can contribute to longer delivery times?

A: Factors such as customs clearance procedures, transportation logistics, and international shipping arrangements can contribute to longer delivery times.

Q: How does Vhandy Ceramics handle potential delays?

A: Vhandy Ceramics strives to minimize potential delays and works closely with shipping partners to expedite the process whenever possible.

Q: Can I get an accurate delivery estimate for my order?

A: Yes, our customer service team can provide you with an estimated delivery time based on your specific order and location. They will also keep you informed throughout the production and shipping process.

Contact

*Your contact won’t be shared with 3rd party.

Shenyang Vhandy Technology Co., Ltd.

Room 401, D11 Block (Shenyang International Software Park), Shenyang, Liaoning, China

Phone/WeChat/WhatsApp

Tel

0086-24-31501218