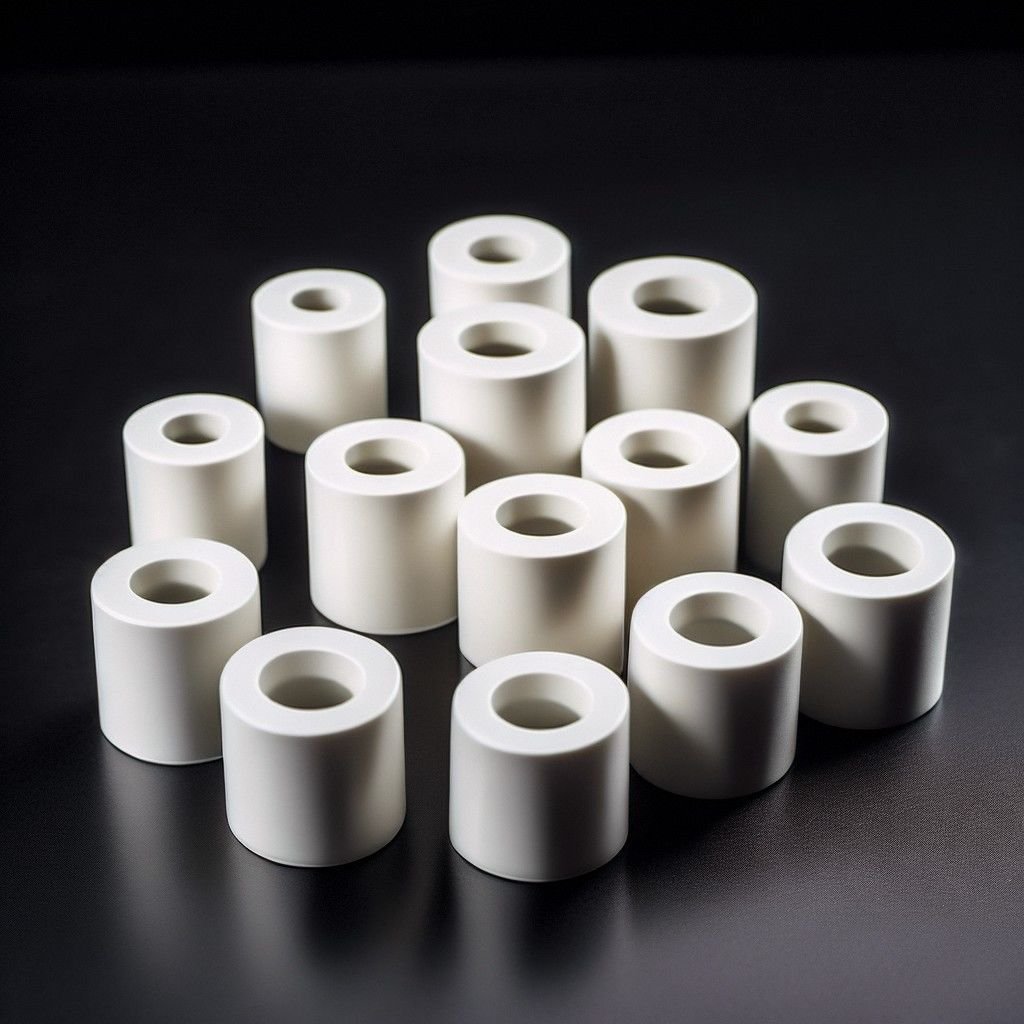

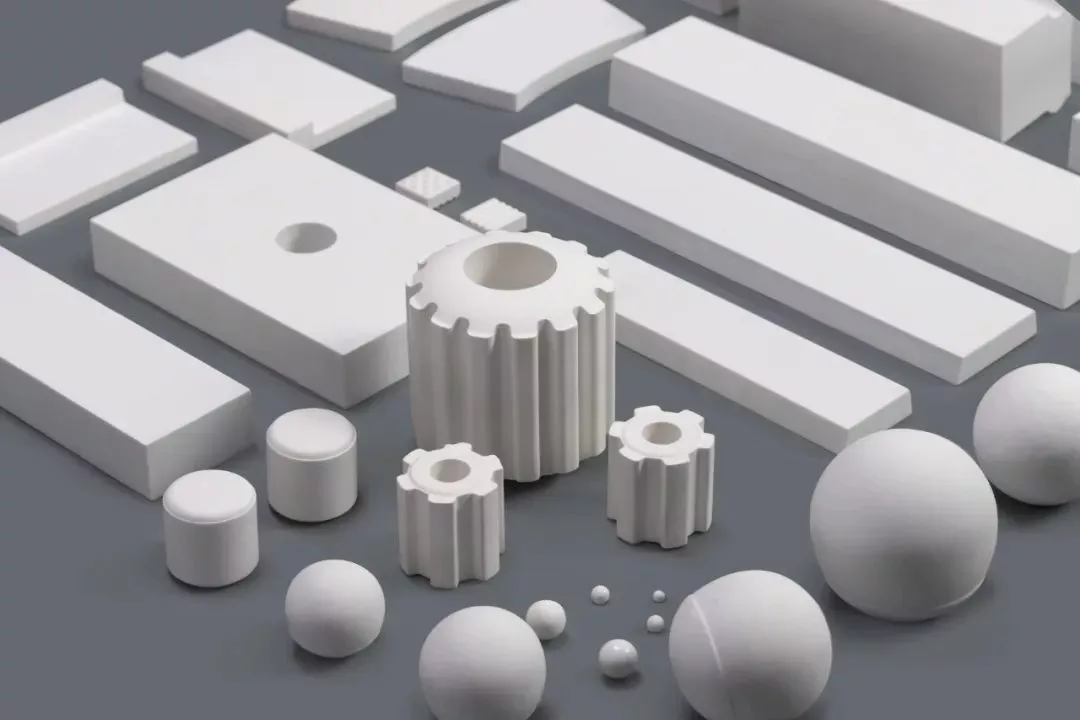

The energy industry is constantly seeking innovative solutions to improve efficiency and sustainability, and industrial ceramics have emerged as a transformative force in this pursuit. Vhandy Ceramics, a leading manufacturer in the field, offers a wide range of advanced ceramic materials that are revolutionizing energy generation and utilization across various sectors. Let’s delve into the remarkable applications of Vhandy Ceramics’ industrial solutions and their significant contributions to the energy industry.

Gas Turbine Power Generation:

Industrial ceramics play a vital role in optimizing gas turbine performance, enhancing energy conversion efficiency, and reducing operational costs. Vhandy Ceramics’ high-temperature ceramic coatings provide exceptional thermal insulation in combustion chambers, minimizing heat loss and maximizing power generation efficiency. Additionally, our corrosion-resistant ceramic materials in nozzle components improve gas flow dynamics, ensuring long-term durability even in harsh operating conditions. These ceramic solutions empower gas turbine power plants to deliver reliable and sustainable electricity generation.

Nuclear Energy:

Nuclear power remains a crucial component of the global energy mix, and Vhandy Ceramics’ industrial ceramics contribute to its safe and efficient operation. In nuclear power plants, our ceramic materials find applications in critical components such as nuclear fuel particles, fuel elements, and heat exchangers. The use of ceramics in encapsulating nuclear fuel particles ensures their stability under high temperatures and radiation exposure. Moreover, ceramic materials in fuel elements exhibit excellent thermal conductivity and corrosion resistance, enabling efficient heat transfer and prolonged lifespan. The ceramic tube bundles in heat exchangers facilitate effective heat exchange, supporting optimal performance and safety in nuclear power plants.

Solar Cells:

Solar energy is a rapidly growing renewable energy source, and Vhandy Ceramics’ industrial ceramics are driving advancements in solar cell technology. Our silicon-based ceramic materials serve as substrates for solar cell panels, providing mechanical support and efficient heat dissipation. By using ceramics in solar cell encapsulation, we enhance their durability and stability, enabling prolonged operation in diverse environmental conditions. With our ceramic solutions, solar cells achieve higher conversion efficiency, leading to increased energy production from clean and renewable sources.

High-Temperature Fuel Cells:

High-temperature fuel cells offer a promising pathway to clean and efficient energy conversion, and Vhandy Ceramics is at the forefront of this technology. Our industrial ceramics are utilized in manufacturing ceramic electrolyte membranes and electrode materials for high-temperature fuel cells. The ceramic electrolytes exhibit high ion conductivity and exceptional chemical stability, enabling efficient ion transport at elevated temperatures. Furthermore, our ceramic electrode materials possess excellent electrocatalytic performance, accelerating reaction rates within fuel cells and maximizing energy conversion efficiency.

In conclusion, Vhandy Ceramics’ industrial solutions are driving significant advancements in the energy industry, supporting improved energy conversion efficiency, high-temperature resistance, corrosion resistance, and chemical stability. Our industrial ceramics find applications in gas turbine power generation, nuclear energy, solar cells, and high-temperature fuel cells. By embracing Vhandy Ceramics’ cutting-edge solutions, the energy industry can achieve greater sustainability, technological progress, and a brighter future.

FAQ

Can you provide samples for me to test? How much does it cost?

We strive to provide ceramic samples that closely meet your requirements to the best of our abilities.

The samples are completely free, but you need to pay the freight.

For samples with unique shapes that require custom molds, we are open to discussing the mold cost in order to accommodate your specific needs.

I don’t know which material of ceramic I need, what should I do?

No worries! Please provide us with more details about your requirements, such as the intended use, desired properties, and any specific characteristics you’re looking for.

With these information, our team can guide you in selecting the most suitable ceramic material for your needs.

What's your trade terms?

We prefer EXW, FOB and CIF as for terms.

T/T, West Union,30% deposit, 70% balance paid before delivery are greatly appreciated.

What is the processing accuracy of ceramics?

| Precision Requirement | Example | Unit |

|---|---|---|

| Surface Flatness | Ra ≤ 0.1 μm | μm |

| Dimensional Accuracy | Tolerance within tens of μm | μm |

| Aperture Precision | Diameter tolerance within a few hundred μm | μm |

| Surface Finish | Ra ≤ 0.2 μm | μm |

We maintain strict processing precision standards, ensuring that our products meet the majority of requirements using our standard manufacturing processes.

However, if you have a need for even higher precision products, please feel free to contact us.

We can discuss your specific requirements and explore customized solutions to meet your exacting standards.

I am concerned about the quality of the product I ordered.

We understand your worries and we maintain stringent quality control standards, and while the occurrence of defects is extremely rare, it is an unavoidable possibility.

If any quality issues arise, we take full responsibility and will expedite the reproduction process at cost price.

Our commitment is to ensure that our products meet the highest quality standards and promptly address any concerns to ensure customer satisfaction.