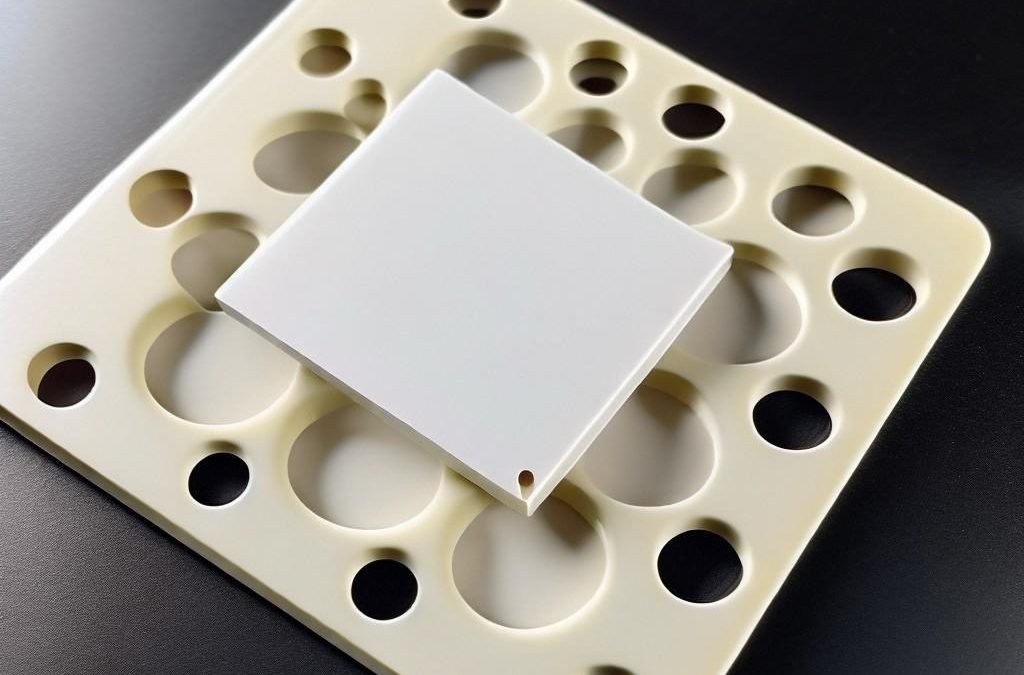

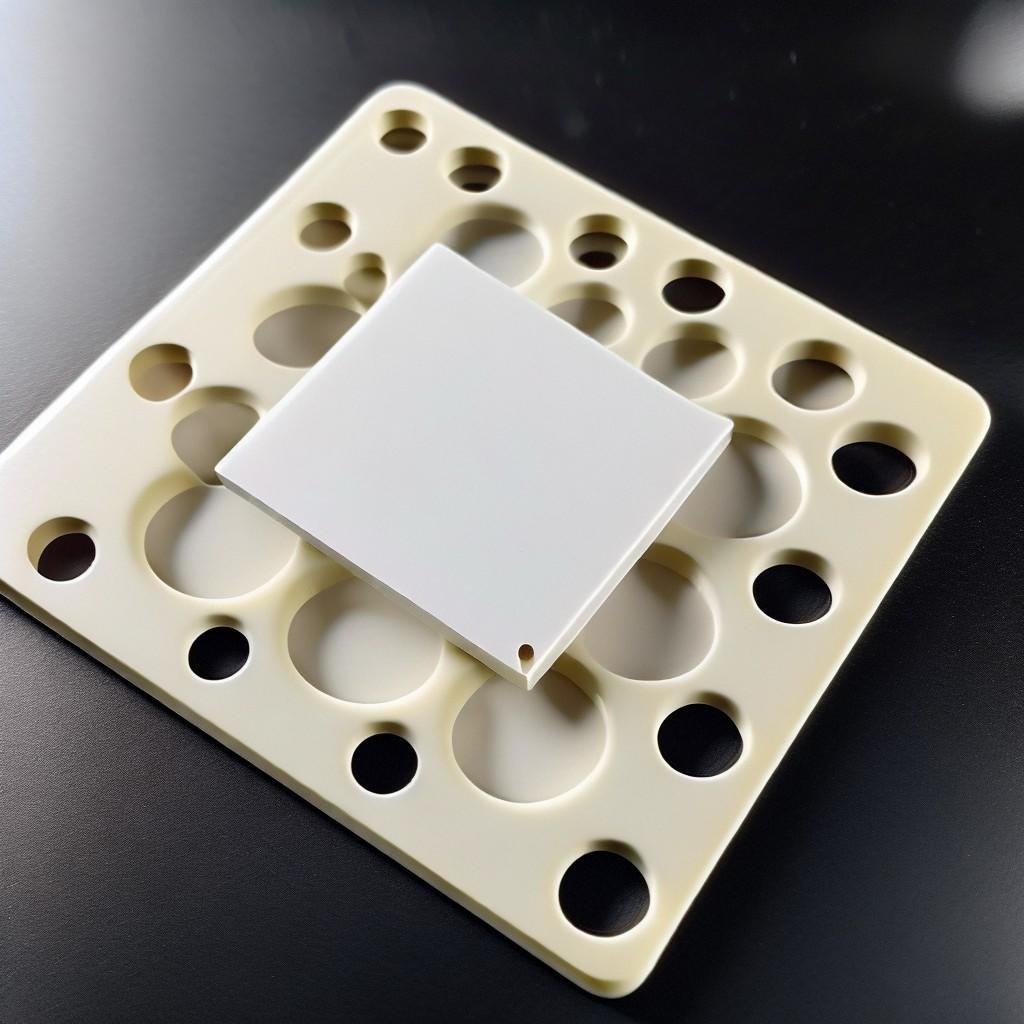

In the dynamic world of industrial ceramics, Vhandy Ceramics stands out as a leading manufacturer, specializing in advanced alumina ceramic substrates with remarkable heat dissipation capabilities. Our alumina ceramic substrates offer a multitude of advantages that make them the perfect choice for various applications requiring efficient heat management. Let’s delve into the exceptional properties and benefits of Vhandy Ceramics’ alumina ceramic substrates.

1. Fast Heat Dissipation:

Alumina ceramic substrates possess a small thermal capacity, ensuring swift heat dissipation. Unlike metallic radiating fins that can be influenced by the “heat ladder” effect, ceramic substrates provide consistent and reliable heat rejection. This leads to improved performance and longevity in heat-intensive applications.

2. High Insulation and Temperature Resistance:

Our alumina ceramic substrates exhibit high insulation properties, enabling them to function reliably in high or low-temperature environments. With exceptional resistance to oxidation, acid, and alkali, they maintain stability even in severe operating conditions. Furthermore, their low thermal expansion coefficient ensures minimal deformation and enhanced thermal management.

3. Multidirectional Heat Rejection:

Alumina ceramic’s unique structure enables multidirectional heat rejection, further enhancing its heat dissipation capabilities. This feature ensures efficient cooling and prevents potential thermal bottlenecks, resulting in optimized performance and increased reliability.

4. Natural Inorganic Material:

Vhandy Ceramics’ alumina ceramic substrates are composed of natural inorganic materials, making them environmentally compliant and exempted from EU regulations. By choosing our ceramic substrates, you prioritize sustainability without compromising on performance.

5. Anti-Interference and Antistatic Properties:

Our ceramic substrates possess effective anti-interference and antistatic properties. Additionally, their moisture absorption characteristics ensure that equipment performance remains unaffected, providing consistent and reliable operation.

6. Fast Heat Dissipation Speed:

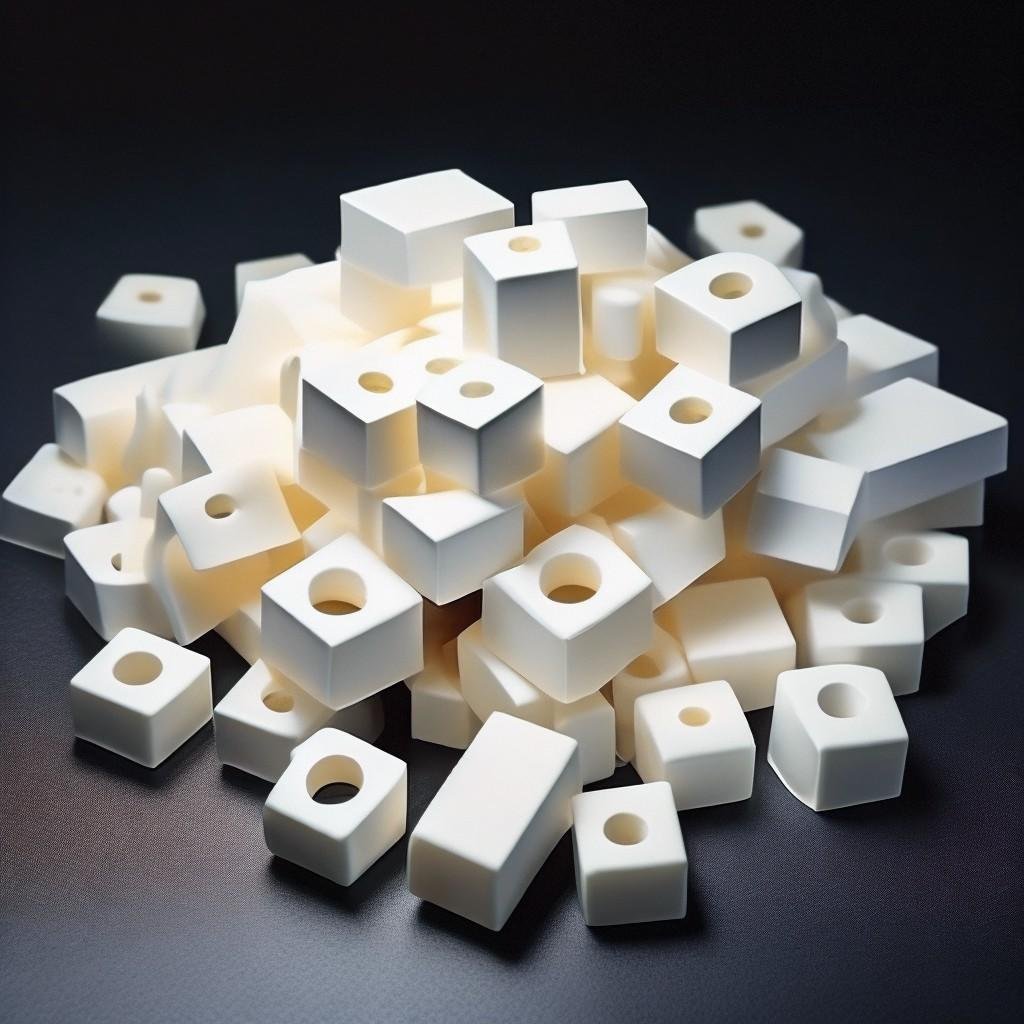

The polycrystalline structure of alumina ceramic facilitates rapid heat dissipation. The micro-porous structure increases the heat dissipation area, significantly enhancing the overall cooling efficiency. In natural environments, alumina ceramic dissipates heat much faster than traditional copper or aluminum counterparts. Moreover, in closed environments, the heat rejection capability of alumina ceramic surpasses metallic materials by 8.8 times, showcasing its exceptional heat dissipation speed.

7. Space-Saving Design:

Alumina ceramic dissipating fins have a compact volume and lightweight, resulting in minimal space occupation. This not only saves on material and freight costs but also allows for efficient and optimized product layout design.

With such exceptional properties, Vhandy Ceramics’ alumina ceramic substrates find wide applications in high-density switching power supplies, high-frequency communication equipment, induction cookers, electrical heat-generating equipment, and more. These substrates enable efficient heat dissipation, ensuring the longevity and optimal performance of your products in demanding environments.

In conclusion, Vhandy Ceramics’ alumina ceramic substrates offer unparalleled advantages in heat dissipation, insulation, and resistance to extreme environments. Leveraging our innovative solutions, you can unlock the full potential of your products in terms of heat management, performance, and reliability. Trust Vhandy Ceramics to deliver cutting-edge alumina ceramic substrates that set new standards in the industry.

FAQ

Can you provide samples for me to test? How much does it cost?

We strive to provide ceramic samples that closely meet your requirements to the best of our abilities.

The samples are completely free, but you need to pay the freight.

For samples with unique shapes that require custom molds, we are open to discussing the mold cost in order to accommodate your specific needs.

I don’t know which material of ceramic I need, what should I do?

No worries! Please provide us with more details about your requirements, such as the intended use, desired properties, and any specific characteristics you’re looking for.

With these information, our team can guide you in selecting the most suitable ceramic material for your needs.

What's your trade terms?

We prefer EXW, FOB and CIF as for terms.

T/T, West Union,30% deposit, 70% balance paid before delivery are greatly appreciated.

What is the processing accuracy of ceramics?

| Precision Requirement | Example | Unit |

|---|---|---|

| Surface Flatness | Ra ≤ 0.1 μm | μm |

| Dimensional Accuracy | Tolerance within tens of μm | μm |

| Aperture Precision | Diameter tolerance within a few hundred μm | μm |

| Surface Finish | Ra ≤ 0.2 μm | μm |

We maintain strict processing precision standards, ensuring that our products meet the majority of requirements using our standard manufacturing processes.

However, if you have a need for even higher precision products, please feel free to contact us.

We can discuss your specific requirements and explore customized solutions to meet your exacting standards.

I am concerned about the quality of the product I ordered.

We understand your worries and we maintain stringent quality control standards, and while the occurrence of defects is extremely rare, it is an unavoidable possibility.

If any quality issues arise, we take full responsibility and will expedite the reproduction process at cost price.

Our commitment is to ensure that our products meet the highest quality standards and promptly address any concerns to ensure customer satisfaction.

Contact

*Your contact won’t be shared with 3rd party.

Shenyang Vhandy Technology Co., Ltd.

Room 401, D11 Block (Shenyang International Software Park), Shenyang, Liaoning, China

Phone/WeChat/WhatsApp

Tel

0086-24-31501218