Industrial Alumina Ceramics

Industrial Alumina Ceramics: High-Performance Solutions for Demanding ApplicationsIn the rapidly evolving landscape of industrial ceramics, alumina (Al₂O₃) ceramics stand out as a cornerstone material due to their exceptional mechanical, thermal, and electrical...

96% Alumina Ceramic Substrate

96% Alumina Ceramic Substrate:Properties, Applications, and Market Trends in Industrial Ceramics Introduction 96% alumina ceramic substrate, a high-performance material renowned for its thermal stability, electrical insulation, and mechanical strength, has become...

95% Alumina Ceramic vs. 99% Alumina Ceramic: How to Choose the Best Material for Your Application

In the field of industrial ceramics, 95% alumina ceramic and 99% alumina ceramic are two of the most commonly used materials. Both exhibit excellent mechanical strength, high-temperature resistance, corrosion resistance, and electrical insulation properties, making...

The reason why alumina ceramic lining is wear-resistant and impact-resistant

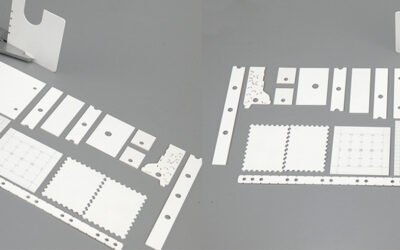

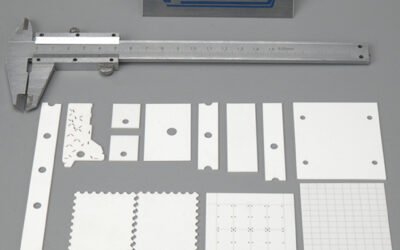

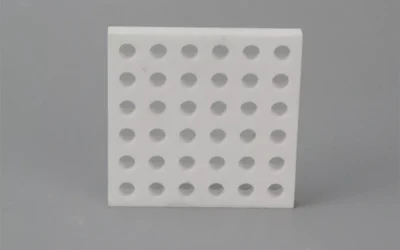

There are many thickness specifications and sizes of wear-resistant ceramic linings. There are three main types that are often used: 10*10, 17.5*17.5, and 20*20. The thinnest is 3mm and the thickest is 20mm. Generally, the appropriate size is selected according to...

Ceramic Structural Parts Process Flow

As an emerging product, ceramic structural parts have high thermal and chemical properties, such as high temperature resistance, corrosion resistance, oxidation resistance, and high hardness of advanced ceramics. The ceramic structural parts produced by our company...

Zirconia ceramic

1.High hardness. With a hardness of 86HRC, it can be made into cold forming tools, shaping molds, wire drawing dies, cutting tools, etc 2.High strength and good toughness. The flexural strength at room temperature can reach 2100MPa, and 1190MPa at 1000℃. The best...

What is the difference between 96% and 99% alumina in ceramic circuit boards?

When designing high-performance electronic devices, alumina (Al2O3) has become the first choice for ceramic printed circuit boards (PCBs) due to its excellent thermoelectric properties. But not all alumina is the same! In this article, we will explore the difference...

About Aluminum Titanate Refractory

Aluminum titanate ceramics 1. The influence of additives on the structure and properties of aluminum titanate refractory: Aluminum titanate refractoryAdvantages: high melting point, low expansion, etc.Disadvantages: low strength, easy to decompose, difficult to...

About the riser

Aluminum titanate ceramics not only have a high melting point (1860°C) and a low thermal expansion coefficient (α≤2.0×10-6/K), but also have the property of not being wetted by many non-ferrous metal melts such as aluminum. Therefore, they are an excellent material...

Characteristics and functions of zirconia ceramic rods

Ceramic rods are made of zirconium oxide or alumina as production materials. Compared with similar products, the advantages are quite significant. It has good wear resistance. So what are the advantages of zirconia ceramic rods?Zirconia ceramic rods have the...

High density calcium silicate insulation board

High-density calcium silicate insulation board is a calcium silicate board with a density of 800-1000KGS/M3 specially developed for the non-ferrous metal industry. It can be used for the transportation, shipping and shaping of molten aluminum and other non-ferrous...

About calcium silicate ceramic plates

With the improvement of people's quality of life and the strengthening of environmental awareness, more and more new materials have appeared on the market to replace traditional materials. The following content is an analysis of the advantages of new calcium silicate...

Contact

*Your contact won’t be shared with 3rd party.

Shenyang Vhandy Technology Co., Ltd.

Room 401, D11 Block (Shenyang International Software Park), Shenyang, Liaoning, China

Phone/WeChat/WhatsApp

Tel

0086-24-31501218