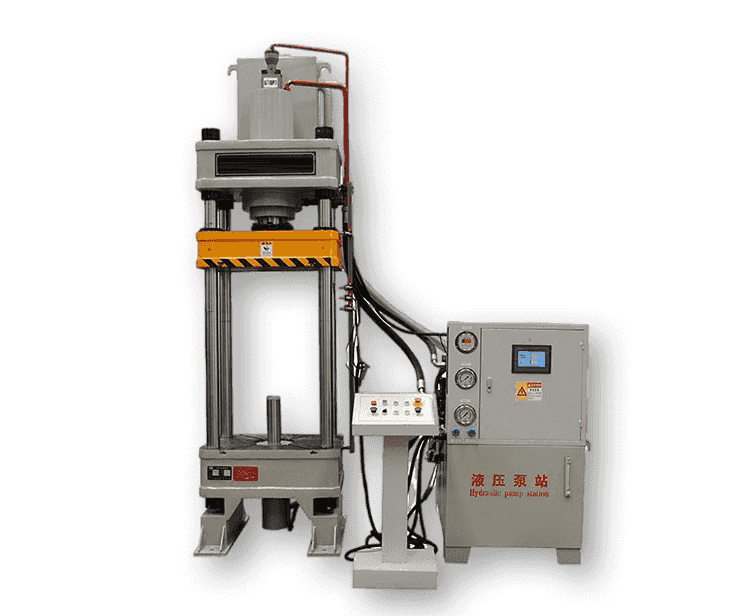

Dry pressing

Dry pressing is to add a certain amount of organic additives (binders, lubricants, plasticizers, defoamers, water reducers, etc.) to the ceramic powder, and shape it in the mold under the action of external pressure.

Advantages

Easy to realize automation

Widely used in industrial production

Disadvantage

During the forming process, the stratification of the green body is often caused by the uneven distribution of radial and axial pressure.

Phenomena such as cracking and uneven density often occur.