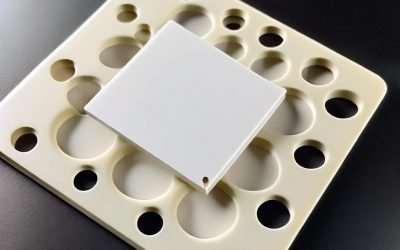

Ceramic Substrates for Efficient Heat Dissipation

In today's rapidly evolving industrial landscape, efficient heat dissipation is crucial for the reliable operation of electronic components and systems. Ceramic substrates have emerged as a preferred choice due to their exceptional thermal conductivity, electrical...

The Ideal Ceramic Materials for Nozzles

Ceramic Nozzles for Sandblasting Machines: Sandblasting is a widely used technique in various industries for surface preparation, cleaning, and finishing applications. The choice of nozzle material plays a crucial role in the efficiency, durability, and overall...

Ceramic Rollers for Glass Production: Key Parameters and Material Selection

Ceramic rollers play a vital role in the glass manufacturing process, ensuring precise control and smooth transportation of glass sheets. Choosing the right ceramic material for rollers is essential to withstand high temperatures, resist wear and chemical corrosion,...

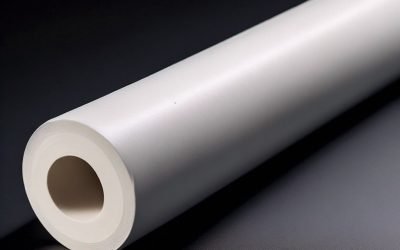

High-Quality Alumina Ceramic Tubes for Industrial Application

Introduction: Alumina ceramic tubes, primarily composed of α-Al2O3 as the main crystal phase, are widely recognized as a superior ceramic material for industrial applications. With alumina content ranging from 75% to 99.9%, these ceramics, classified based on their...

Elevate Gas Turbine Engine with High-Temperature Ceramics

In the realm of gas turbine engine manufacturing, the demand for materials with exceptional high-temperature stability and wear resistance is paramount. Different types of ceramics, such as zirconia, alumina, and mullite ceramics, have emerged as reliable choices for...

Voordeel van aluminiumoxide keramisch substraat

In the dynamic world of industrial ceramics, Vhandy Ceramics stands out as a leading manufacturer, specializing in advanced alumina ceramic substrates with remarkable heat dissipation capabilities. Our alumina ceramic substrates offer a multitude of advantages that...

Toepassing van industriële keramiek in de energie-industrie

The energy industry is constantly seeking innovative solutions to improve efficiency and sustainability, and industrial ceramics have emerged as a transformative force in this pursuit. Vhandy Ceramics, a leading manufacturer in the field, offers a wide range of...

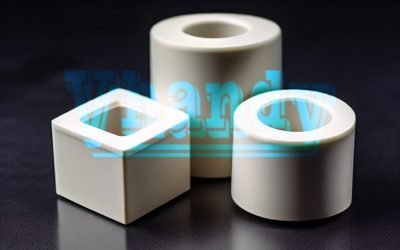

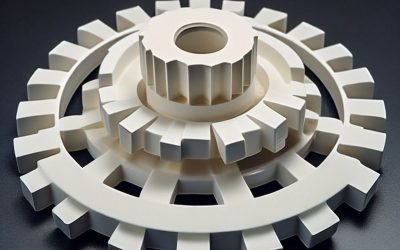

Application and advantages of industrial ceramic rollers

Unveiling the Applications: Industrial ceramic rolls find extensive applications across a multitude of industries, ranging from steel and aluminum production to glass manufacturing and paper processing. Thanks to their exceptional heat resistance, hardness, and wear...

Boost Industrial Processes with Advanced Ceramic Rollers

Innovation knows no bounds when it comes to specialized ceramics. These remarkable materials possess an array of exceptional properties that make them stand out in the world of advanced engineering. Let's dive into some of the key features that make specialized...

Sterkte Breuktaaiheid van Verschillende Industriële Keramiek

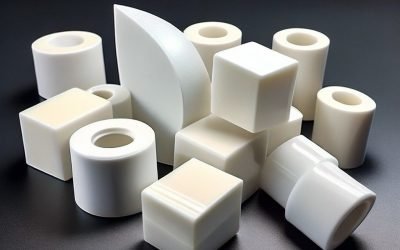

Vhandy Ceramics, a renowned industrial ceramics manufacturer, takes pride in delivering high-performance heat-resistant materials that excel in demanding industrial environments. Understanding the strength and fracture toughness of different ceramic products is...

Manufacturing Temperatures of Various Industrial Ceramic

As a leading industrial ceramics manufacturer, Vhandy Ceramics takes pride in offering a wide range of heat-resistant materials that excel in demanding environments. Understanding the manufacturing temperatures of different ceramic products is vital for industries...

Vhandy Ceramics’ High-Temperature Resistant Solutions

In the world of industrial applications, the demand for heat-resistant ceramics that can withstand extreme temperatures is paramount. If you are a discerning industrial ceramic buyer seeking reliable and durable materials, look no further than Vhandy Ceramics. Our...

Neem contact op met

*Uw contact wordt niet gedeeld met derden.

Shenyang Vhandy Technology Co, Ltd.

Kamer 401, D11 Blok (Shenyang International Software Park), Shenyang, Liaoning, China

Telefoon/WeChat/WhatsApp

Tel

0086-24-31501218