High-density calcium silicate insulation board is a calcium silicate board with a density of 800-1000KGS/M3 specially developed for the non-ferrous metal industry. It can be used for the transportation, shipping and shaping of molten aluminum and other non-ferrous metals, and can also be used in the glass industry. of fetus. In addition to its own thermal insulation properties, its non-stick aluminum characteristics are fully utilized. It has high strength and good processability, and can be used to process precision-sized products and complex components with CNC machine tools. There are two types, glass fiber reinforced and carbon fiber reinforced.

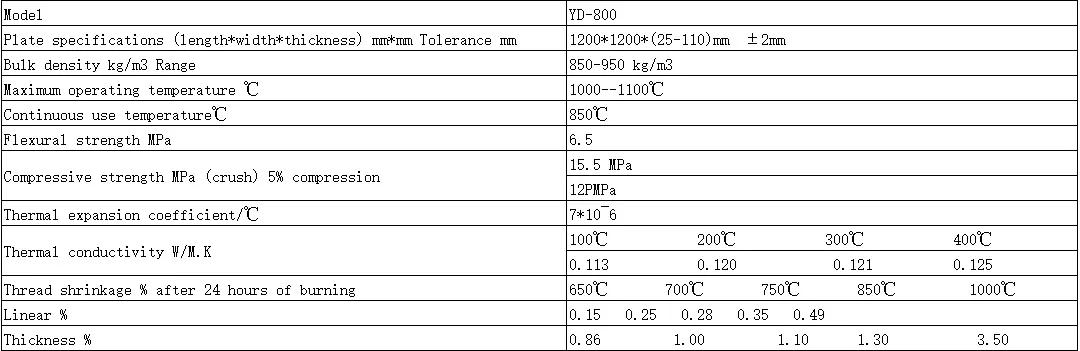

1.HDYD-800 glass fiber reinforced calcium silicate board

A. Features and Benefits

Low thermal conductivity, less heat loss at high temperatures

Not wetted by molten aluminum

Thermal shock resistance

Excellent machining performance

Asbestos free

B. Purpose

Automotive glass molds, droppers, flow tubes, hot top rings, brake pins, ears, floats, flow channels

C. Chemical composition

SiO2………………49—52%

CaO……………… 39—42%

AlO3………… 0.4—0.5%

MgO……………… 0.5—0.7%

Fe2O3………… 0.3—0.4%

Na2-K2O………… 0.9—0.1%

Burn loss……………… 5–9%

D. Specifications and technical indicators

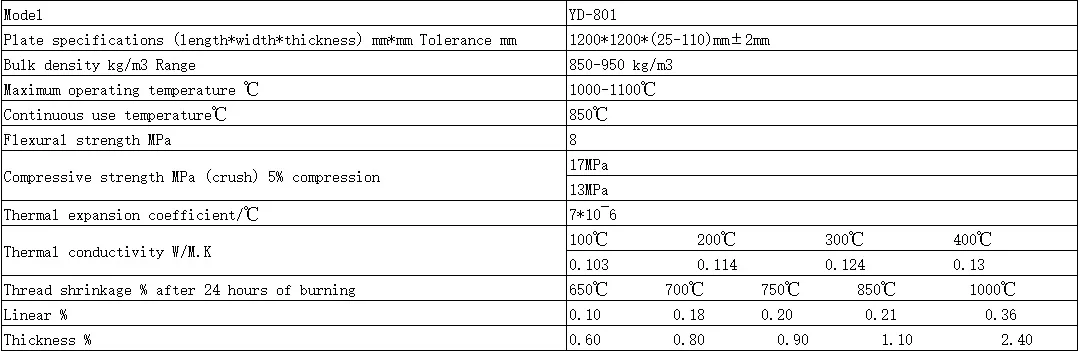

2. HDYD-801 carbon fiber reinforced calcium silicate board

A. Features and Benefits

The addition of carbon fiber gives it higher high-temperature strength and other high-temperature properties

Low thermal conductivity, less heat loss at high temperatures

Not wetted by molten aluminum

Thermal shock resistance

Excellent machining performance

Asbestos free

B. Purpose

Keep furnace lining, continuous caster nozzle material, adapter plate, buffer plate, gasket, plug head, launder lining, baffle, float, standpipe, filter box

C. chemical composition

SiO2………………49—52%

CaO………………..39—42%

AlO3……………….0.4—0.5%

MgO……………… 0.5—0.7%

Fe2O3………………. 0.3—0.4%

Na2-K2O………… 0.9—0.1%

Burn loss……………… 5–9%

D. Specifications and technical indicators

With the continuous innovation and development of science and technology, I believe that more and more innovative decoration materials will enter daily life in the future. If you have any needs about industrial ceramic materials, please feel free to contact us at any time.With the continuous innovation and development of science and technology, I believe that more and more innovative decoration materials will enter daily life in the future. If you have any needs about industrial ceramic materials, please feel free to contact us at any time 0086-17702411651