In the realm of gas turbine engine manufacturing, the demand for materials with exceptional high-temperature stability and wear resistance is paramount. Different types of ceramics, such as zirconia, alumina, and mullite ceramics, have emerged as reliable choices for various engine components due to their remarkable properties.

Zirconia ceramics find various applications in gas turbine engines due to their exceptional properties. Some specific applications of zirconia ceramics in gas turbine engines include:

Thermal Barrier Coatings (TBCs):

Zirconia ceramics are widely used as the primary material for thermal barrier coatings in gas turbine engines. These coatings are applied to components such as turbine blades and vanes to protect them from high-temperature environments. Zirconia’s low thermal conductivity acts as an insulating layer, reducing heat transfer to the underlying metal substrate and allowing the engine to operate at higher temperatures.

Zirconia ceramics are also employed in the manufacturing of nozzles used in gas turbine engines. Nozzles play a critical role in directing the flow of hot gases and ensuring efficient combustion. Zirconia’s high-temperature stability and wear resistance make it suitable for withstanding the harsh operating conditions and erosion caused by high-velocity gases and abrasive particles.

Combustion Liners and Flame Holders:

Zirconia ceramics can be utilized in combustion liners and flame holders within gas turbine engines. Combustion liners provide a controlled environment for fuel combustion, while flame holders stabilize and anchor the flame within the combustion chamber. Zirconia’s high-temperature stability and resistance to thermal shock make it an excellent choice for these components subjected to extreme heat and rapid temperature changes.

Spark Plugs:

Zirconia ceramics can be used in spark plugs for gas turbine engines. These spark plugs play a crucial role in igniting the fuel-air mixture in the combustion chamber. Zirconia’s electrical insulation properties and high-temperature stability make it suitable for withstanding the electrical and thermal stresses encountered during the ignition process.

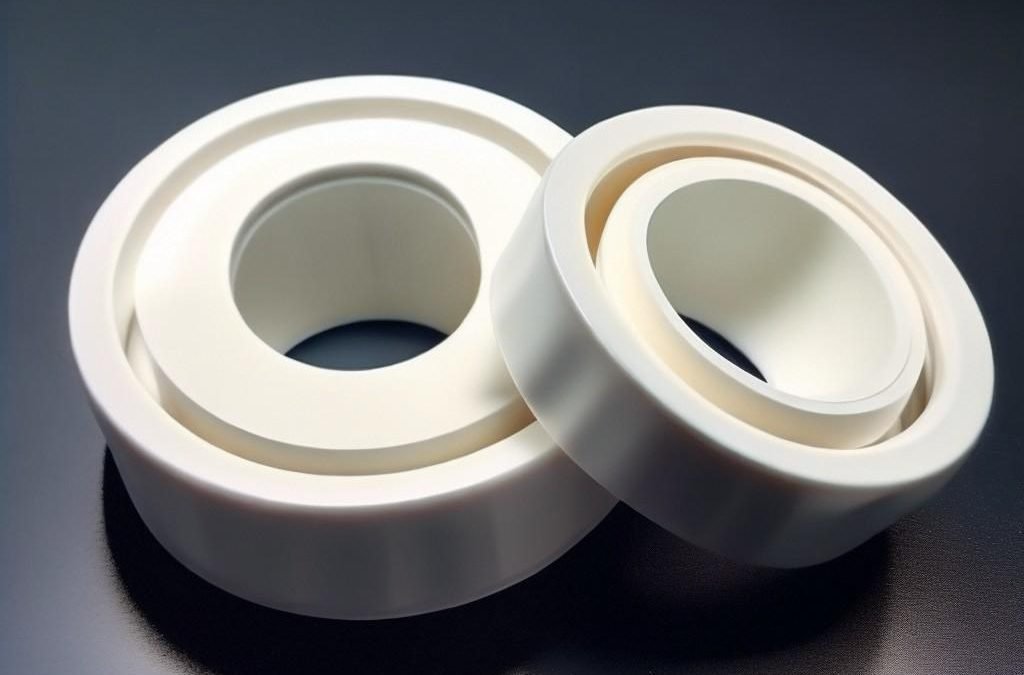

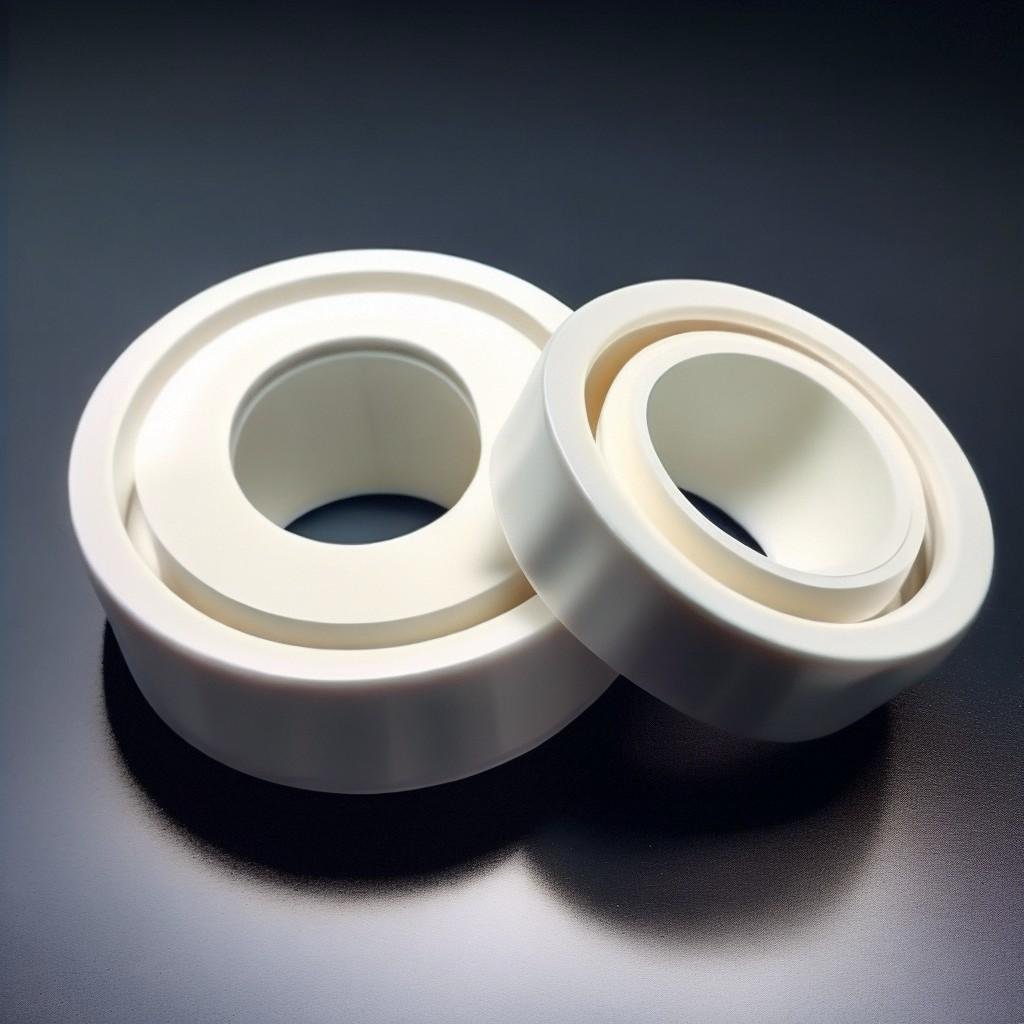

Bearings and Seals:

In certain gas turbine engine designs, zirconia ceramics can be employed in bearings and seals. Zirconia’s low coefficient of friction, excellent wear resistance, and high-temperature stability make it suitable for reducing friction and ensuring smooth operation between rotating components and stationary parts.

By leveraging the exceptional properties of zirconia ceramics, gas turbine engine manufacturers can enhance the performance, durability, and efficiency of their engines, ultimately leading to improved overall engine operation and reduced maintenance requirements.

At Vhandy Ceramics, we specialize in providing high-quality industrial ceramics that meet the stringent requirements of the gas turbine industry. Let’s compare the key properties of zirconia, alumina, and mullite ceramics in the table below:

| Property | Zirconia Ceramics | Alumina Ceramics | Mullite Ceramics |

|---|---|---|---|

| High-Temperature Stability | Excellent | Good | Excellent |

| Thermal Conductivity | Low | High | Low |

| Wear Resistance | Outstanding | Good | Excellent |

| Corrosion Resistance | Exceptional | Excellent | Excellent |

| Density | High | High | Moderate |

Zirconia ceramics, known for their exceptional high-temperature stability and wear resistance, are widely used for manufacturing thermal barrier coatings and nozzles in gas turbine engines. They offer reliable performance even under extreme heat conditions, ensuring the longevity of engine components.

Alumina ceramics, on the other hand, exhibit good high-temperature stability and excellent corrosion resistance. They are commonly used for components that require high thermal conductivity, such as heat exchangers and insulators.

Mullite ceramics, with their excellent high-temperature stability, wear resistance, and corrosion resistance, are suitable for a wide range of gas turbine engine components. They offer a balance of properties that make them ideal for applications where both thermal and mechanical stresses are present.

As a leading industrial ceramics manufacturer, Vhandy Ceramics is committed to delivering products of the highest quality. Our advanced manufacturing techniques and stringent quality control processes ensure that our ceramics meet the industry’s most demanding standards. We work closely with our clients, understanding their specific needs, and providing customized solutions that optimize engine performance.

Partner with Vhandy Ceramics and experience the exceptional benefits of our high-quality ceramics for gas turbine engine manufacturing. Contact us today to discuss your requirements and witness the difference our expertise can make.

FAQ

Can you provide samples for me to test? How much does it cost?

We strive to provide ceramic samples that closely meet your requirements to the best of our abilities.

The samples are completely free, but you need to pay the freight.

For samples with unique shapes that require custom molds, we are open to discussing the mold cost in order to accommodate your specific needs.

I don’t know which material of ceramic I need, what should I do?

No worries! Please provide us with more details about your requirements, such as the intended use, desired properties, and any specific characteristics you’re looking for.

With these information, our team can guide you in selecting the most suitable ceramic material for your needs.

What's your trade terms?

We prefer EXW, FOB and CIF as for terms.

T/T, West Union,30% deposit, 70% balance paid before delivery are greatly appreciated.

What is the processing accuracy of ceramics?

| Precision Requirement | Example | Unit |

|---|---|---|

| Surface Flatness | Ra ≤ 0.1 μm | μm |

| Dimensional Accuracy | Tolerance within tens of μm | μm |

| Aperture Precision | Diameter tolerance within a few hundred μm | μm |

| Surface Finish | Ra ≤ 0.2 μm | μm |

We maintain strict processing precision standards, ensuring that our products meet the majority of requirements using our standard manufacturing processes.

However, if you have a need for even higher precision products, please feel free to contact us.

We can discuss your specific requirements and explore customized solutions to meet your exacting standards.

I am concerned about the quality of the product I ordered.

We understand your worries and we maintain stringent quality control standards, and while the occurrence of defects is extremely rare, it is an unavoidable possibility.

If any quality issues arise, we take full responsibility and will expedite the reproduction process at cost price.

Our commitment is to ensure that our products meet the highest quality standards and promptly address any concerns to ensure customer satisfaction.

Contact

*Your contact won’t be shared with 3rd party.

Shenyang Vhandy Technology Co., Ltd.

Room 401, D11 Block (Shenyang International Software Park), Shenyang, Liaoning, China

Phone/WeChat/WhatsApp

Tel

0086-24-31501218