Unveiling the Applications:

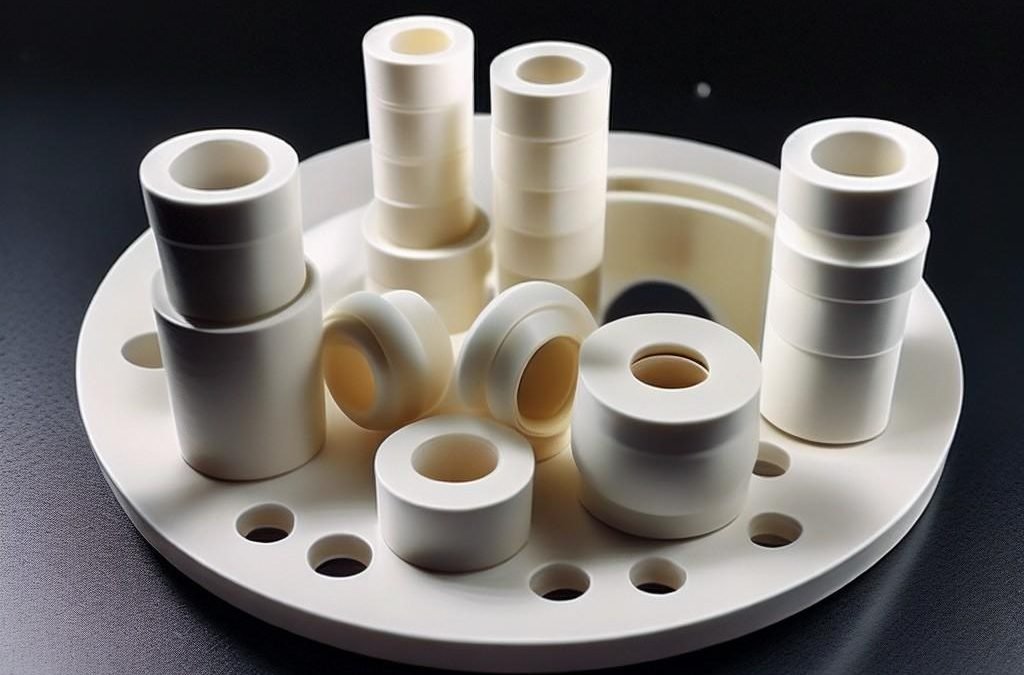

Industrial ceramic rolls find extensive applications across a multitude of industries, ranging from steel and aluminum production to glass manufacturing and paper processing. Thanks to their exceptional heat resistance, hardness, and wear resistance, these ceramic rolls have become indispensable components in critical processes.

In the steel industry, industrial ceramic rollers play a crucial role in the continuous casting and hot rolling processes. They ensure precise shaping and cooling of molten steel, resulting in high-quality finished products. The outstanding wear resistance of ceramic rolls significantly reduces maintenance downtime, leading to increased productivity and cost savings.

Similarly, in the aluminum industry, ceramic rolls are employed in the hot rolling of aluminum sheets. Their remarkable thermal stability enables efficient heat transfer, ensuring uniform thickness and surface finish of the rolled sheets. By minimizing surface defects and improving productivity, our ceramic rolls contribute to higher yield and improved customer satisfaction.

Moreover, industrial ceramic rolls find applications in the glass industry, where they facilitate the smooth and precise movement of glass sheets during the manufacturing process. Their non-reactive nature and excellent thermal shock resistance make them ideal for handling molten glass at high temperatures, ensuring consistent quality and minimizing production bottlenecks.

Unleashing the Benefits:

The utilization of industrial ceramic rolls offers a multitude of benefits, making them a preferred choice for discerning customers:

Exceptional Durability:

Vhandy Ceramics’ industrial ceramic rolls are engineered to withstand the most demanding operating conditions, ensuring long-lasting performance and minimal wear. This durability translates into reduced maintenance costs and increased operational efficiency.

High Heat Resistance:

With an impressive ability to withstand extreme temperatures, our ceramic rolls guarantee reliable performance even in environments with rapid temperature fluctuations. This resilience enhances process stability, reduces downtime, and improves overall productivity.

Superior Wear Resistance:

The inherent hardness and wear resistance of industrial ceramic rolls enable them to endure heavy loads, abrasive materials, and repetitive motion without compromising their performance. This results in extended service life and reduced replacement frequency, leading to substantial cost savings.

Enhanced Product Quality:

By offering precise control and stability in critical processes, ceramic rolls contribute to improved product quality. Their excellent surface finish and dimensional accuracy ensure consistent results, meeting the stringent standards of various industries.

Environmental Friendliness:

Industrial ceramic rolls are environmentally friendly alternatives to traditional rolls made from steel or other materials. They are non-toxic, non-polluting, and have a significantly lower carbon footprint, aligning with sustainable manufacturing practices.

At Vhandy Ceramics, we are committed to delivering cutting-edge solutions that redefine industrial processes.

Our industrial ceramic rolls epitomize the perfect blend of advanced materials, rigorous quality control, and innovative engineering. Partner with us to unlock the true potential of your industry.

FAQ

Can you provide samples for me to test? How much does it cost?

We strive to provide ceramic samples that closely meet your requirements to the best of our abilities.

The samples are completely free, but you need to pay the freight.

For samples with unique shapes that require custom molds, we are open to discussing the mold cost in order to accommodate your specific needs.

I don’t know which material of ceramic I need, what should I do?

No worries! Please provide us with more details about your requirements, such as the intended use, desired properties, and any specific characteristics you’re looking for.

With these information, our team can guide you in selecting the most suitable ceramic material for your needs.

What's your trade terms?

We prefer EXW, FOB and CIF as for terms.

T/T, West Union,30% deposit, 70% balance paid before delivery are greatly appreciated.

What is the processing accuracy of ceramics?

| Precision Requirement | Example | Unit |

|---|---|---|

| Surface Flatness | Ra ≤ 0.1 μm | μm |

| Dimensional Accuracy | Tolerance within tens of μm | μm |

| Aperture Precision | Diameter tolerance within a few hundred μm | μm |

| Surface Finish | Ra ≤ 0.2 μm | μm |

We maintain strict processing precision standards, ensuring that our products meet the majority of requirements using our standard manufacturing processes.

However, if you have a need for even higher precision products, please feel free to contact us.

We can discuss your specific requirements and explore customized solutions to meet your exacting standards.

I am concerned about the quality of the product I ordered.

We understand your worries and we maintain stringent quality control standards, and while the occurrence of defects is extremely rare, it is an unavoidable possibility.

If any quality issues arise, we take full responsibility and will expedite the reproduction process at cost price.

Our commitment is to ensure that our products meet the highest quality standards and promptly address any concerns to ensure customer satisfaction.