Industrial Alumina Ceramics: High-Performance Solutions for Demanding Applications

In the rapidly evolving landscape of industrial ceramics, alumina (Al₂O₃) ceramics stand out as a cornerstone material due to their exceptional mechanical, thermal, and electrical properties. As search trends highlight growing interest in advanced ceramics for sectors like aerospace, semiconductor manufacturing, and energy, alumina ceramics remain a focal point for engineers and procurement specialists. This article explores the latest advancements, applications, and benefits of industrial alumina ceramics, aligning with current market demands and technological innovations.

1. Key Properties of Alumina Ceramics

Alumina ceramics are prized for their high purity, hardness, and resistance to extreme conditions. Modern manufacturing techniques now enable the production of alumina ceramics with:

Purity levels exceeding 99%, enhancing density (up to 3.94–3.96 g/cm³) and mechanical strength.

Superior thermal stability, withstanding temperatures up to 1,800°C, ideal for furnace linings and molten metal handling.

Excellent electrical insulation, critical for applications in electronics and high-voltage systems.

These properties make alumina ceramics indispensable in industries requiring precision, durability, and reliability.

2. Leading Applications Driving Market Demand

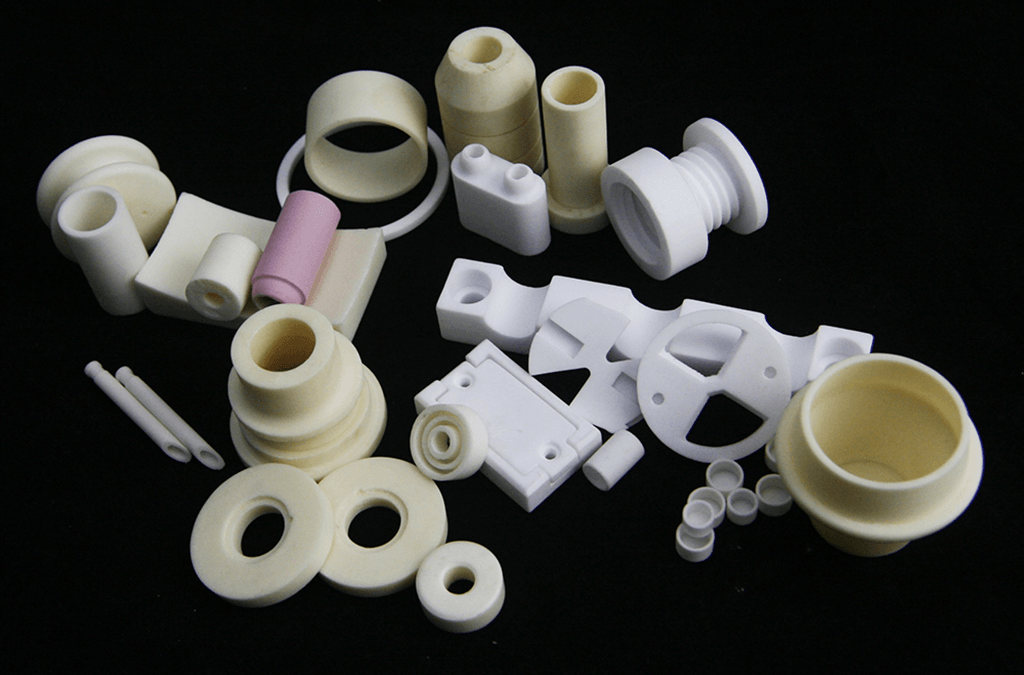

Metal Production and Processing

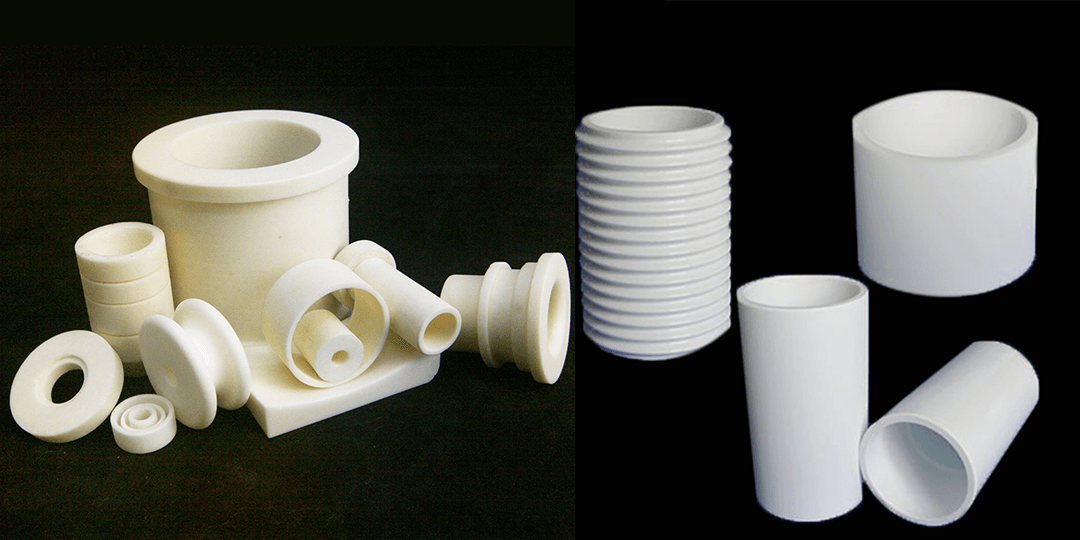

Alumina ceramics are widely used in crucibles, tubes, and liners for molten metal handling. Their resistance to thermal shock and chemical corrosion ensures longevity in environments like steelmaking and aluminum smelting.

Semiconductor and Electronics Manufacturing

High-purity alumina substrates and insulators are essential for semiconductor fabrication, providing stable performance in plasma etching and thin-film deposition processes.

Energy and Petrochemical Industries

In catalytic converters and wear-resistant components, alumina ceramics improve efficiency in harsh chemical environments, reducing downtime and maintenance costs.

Medical and Aerospace

Their biocompatibility and lightweight nature make alumina ceramics suitable for implants, while their thermal resistance supports aerospace components like turbine blades.

3. Innovations in Alumina Ceramic Production

Recent studies emphasize the importance of raw material selection. For instance, high-purity alumina grades like Almatis CT 3000 SG (Germany) achieve superior sintered densities (3.94–3.96 g/cm³) compared to lower-grade alternatives. Advanced sintering techniques and additive manufacturing now enable complex geometries, broadening applications in custom components and kiln furniture.

4. Global Supply Chain and Custom Solutions

China dominates alumina ceramic production, with manufacturers like Hunan Xuecheng and Shenzhen Hard Precision Ceramic offering ISO-certified, customizable solutions. Meanwhile, established suppliers like Anderman Industrial Ceramics provide global support for specialized applications, from vacuum kiln furniture to electrical insulation systems.

5. Future Trends and Sustainability

The push for energy efficiency and automation is driving demand for alumina ceramics in smart manufacturing. Innovations such as RO₂-modified ceramics (e.g., ZrO₂ or CeO₂ additives) enhance thermal cycling resistance, extending product lifespans in extreme conditions. Additionally, the rise of renewable energy and electric vehicles is expected to further boost alumina ceramic usage in battery components and power generation systems.

Conclusion

Industrial alumina ceramics continue to redefine performance benchmarks across industries. By leveraging high-purity materials, advanced manufacturing, and global expertise, businesses can address challenges in wear resistance, thermal management, and precision engineering. For tailored solutions, partnering with certified suppliers ensures access to cutting-edge alumina ceramic products tailored to your operational needs.

Explore our range of alumina ceramics to discover how this versatile material can elevate your industrial processes.

Contact us: https://vhandy.com/contact-us/