In the realm of gas turbine engine manufacturing, the demand for materials with exceptional high-temperature stability and wear resistance is paramount. Different types of ceramics, such as zirkonia, aluminiumoxide, and mullite ceramics, have emerged as reliable choices for various engine components due to their remarkable properties.

Zirconia ceramics find various applications in gas turbine engines due to their exceptional properties. Some specific applications of zirconia ceramics in gas turbine engines include:

Thermal Barrier Coatings (TBCs):

Zirconia ceramics are widely used as the primary material for thermal barrier coatings in gas turbine engines. These coatings are applied to components such as turbine blades and vanes to protect them from high-temperature environments. Zirconia’s low thermal conductivity acts as an insulating layer, reducing heat transfer to the underlying metal substrate and allowing the engine to operate at higher temperatures.

Zirconia ceramics are also employed in the manufacturing of nozzles used in gas turbine engines. Nozzles play a critical role in directing the flow of hot gases and ensuring efficient combustion. Zirconia’s high-temperature stability and wear resistance make it suitable for withstanding the harsh operating conditions and erosion caused by high-velocity gases and abrasive particles.

Combustion Liners and Flame Holders:

Zirconia ceramics can be utilized in combustion liners and flame holders within gas turbine engines. Combustion liners provide a controlled environment for fuel combustion, while flame holders stabilize and anchor the flame within the combustion chamber. Zirconia’s high-temperature stability and resistance to thermal shock make it an excellent choice for these components subjected to extreme heat and rapid temperature changes.

Spark Plugs:

Zirconia ceramics can be used in spark plugs for gas turbine engines. These spark plugs play a crucial role in igniting the fuel-air mixture in the combustion chamber. Zirconia’s electrical insulation properties and high-temperature stability make it suitable for withstanding the electrical and thermal stresses encountered during the ignition process.

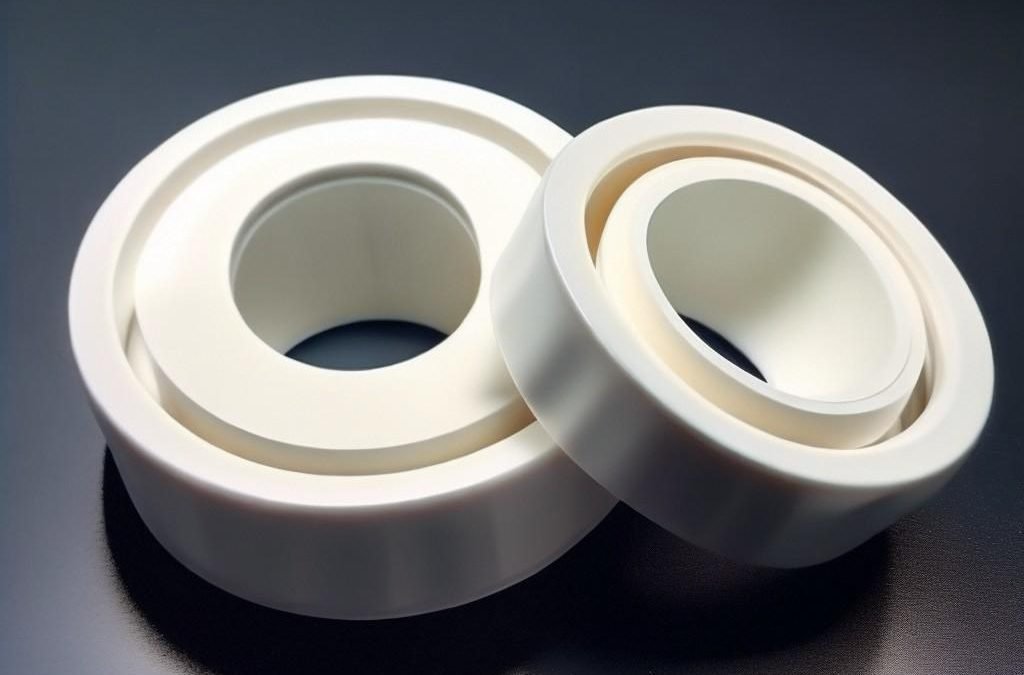

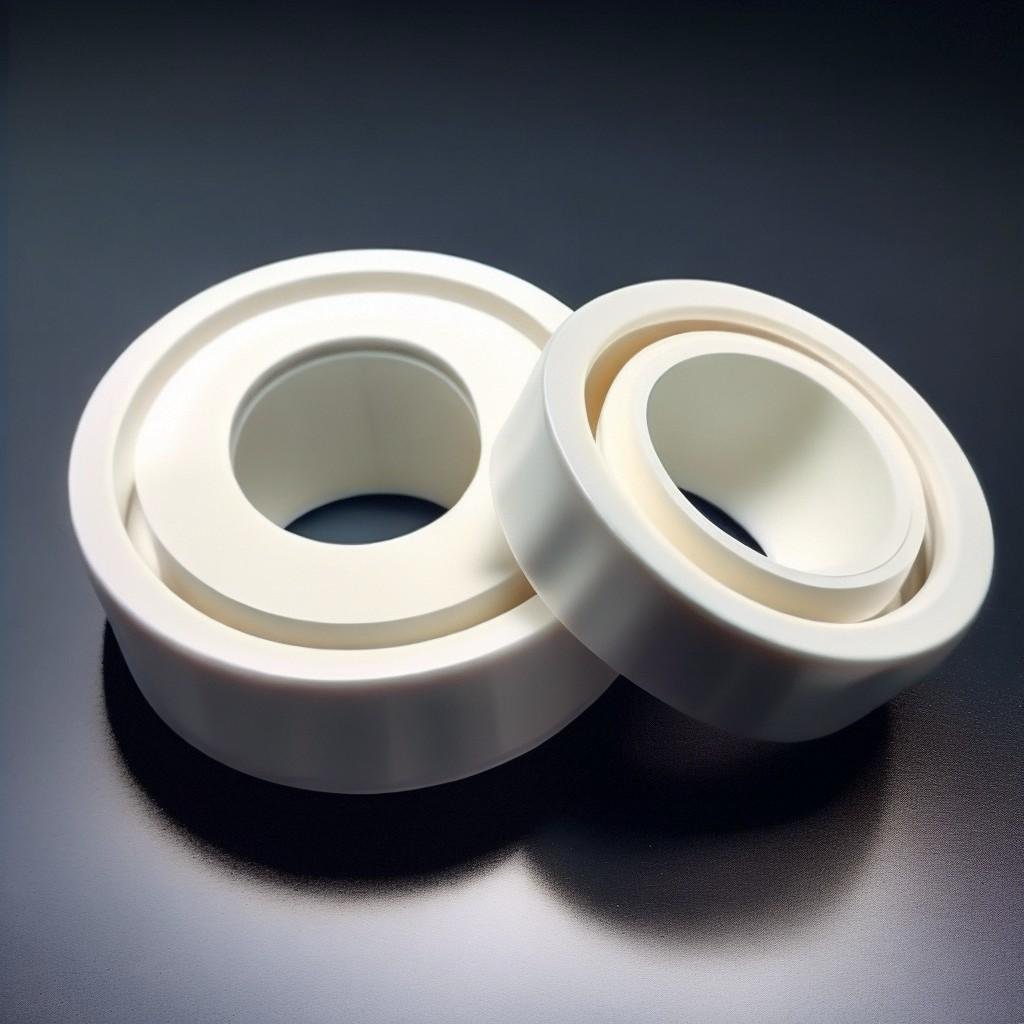

Bearings and Seals:

In certain gas turbine engine designs, zirconia ceramics can be employed in bearings and seals. Zirconia’s low coefficient of friction, excellent wear resistance, and high-temperature stability make it suitable for reducing friction and ensuring smooth operation between rotating components and stationary parts.

By leveraging the exceptional properties of zirconia ceramics, gas turbine engine manufacturers can enhance the performance, durability, and efficiency of their engines, ultimately leading to improved overall engine operation and reduced maintenance requirements.

At Vhandy Ceramics, we specialize in providing high-quality industrial ceramics that meet the stringent requirements of the gas turbine industry. Let’s compare the key properties of zirconia, alumina, and mullite ceramics in the table below:

| Eigendom | Zirkoonoxide keramiek | Aluminiumoxide keramiek | Mullite Ceramics |

|---|---|---|---|

| High-Temperature Stability | Excellent | Good | Excellent |

| Thermische geleidbaarheid | Low | High | Low |

| Wear Resistance | Outstanding | Good | Excellent |

| Corrosion Resistance | Exceptional | Excellent | Excellent |

| Dichtheid | High | High | Moderate |

Zirconia ceramics, known for their exceptional high-temperature stability and wear resistance, are widely used for manufacturing thermal barrier coatings and nozzles in gas turbine engines. They offer reliable performance even under extreme heat conditions, ensuring the longevity of engine components.

Alumina ceramics, on the other hand, exhibit good high-temperature stability and excellent corrosion resistance. They are commonly used for components that require high thermal conductivity, such as heat exchangers and insulators.

Mullite ceramics, with their excellent high-temperature stability, wear resistance, and corrosion resistance, are suitable for a wide range of gas turbine engine components. They offer a balance of properties that make them ideal for applications where both thermal and mechanical stresses are present.

As a leading industrial ceramics manufacturer, Vhandy Ceramics is committed to delivering products of the highest quality. Our advanced manufacturing techniques and stringent quality control processes ensure that our ceramics meet the industry’s most demanding standards. We work closely with our clients, understanding their specific needs, and providing customized solutions that optimize engine performance.

Partner with Vhandy Ceramics and experience the exceptional benefits of our high-quality ceramics for gas turbine engine manufacturing. Contact us today to discuss your requirements and witness the difference our expertise can make.

FAQ

Kunt u monsters leveren die ik kan testen? Hoeveel kost het?

We streven ernaar om keramische monsters te leveren die zo goed mogelijk aan uw eisen voldoen.

De monsters zijn volledig gratismaar je moet de vracht betalen.

Voor monsters met unieke vormen waarvoor aangepaste mallen nodig zijn, staan we open om de matrijskosten te bespreken zodat we aan uw specifieke behoeften kunnen voldoen.

Ik weet niet welk materiaal keramiek ik nodig heb, wat moet ik doen?

Geen zorgen! Geef ons meer details over uw vereisten, zoals het beoogde gebruik, de gewenste eigenschappen en de specifieke kenmerken die u zoekt.

Met deze informatie kan ons team u begeleiden bij het selecteren van het meest geschikte keramische materiaal voor uw behoeften.

Wat zijn je handelsvoorwaarden?

We geven de voorkeur aan EXW, FOB en CIF als voorwaarden.

T/T, het Westenunie, 30% storting, 70% saldo dat vóór levering wordt betaald worden zeer gewaardeerd.

Wat is de verwerkingsnauwkeurigheid van keramiek?

| Nauwkeurigheidsvereiste | Voorbeeld | Eenheid |

|---|---|---|

| Vlakheid oppervlak | Ra ≤ 0,1 μm | μm |

| Dimensionale nauwkeurigheid | Tolerantie binnen tientallen μm | μm |

| Nauwkeurigheid diafragma | Diametertolerantie binnen een paar honderd μm | μm |

| Afwerking oppervlak | Ra ≤ 0,2 μm | μm |

We hanteren strenge normen voor de verwerkingsprecisie en zorgen ervoor dat onze producten aan de meeste eisen voldoen met behulp van onze standaardproductieprocessen.

Als je echter behoefte hebt aan producten met een nog hogere precisie, neem dan gerust contact met ons op.

We kunnen uw specifieke vereisten bespreken en aangepaste oplossingen zoeken om aan uw strenge normen te voldoen.

Ik maak me zorgen over de kwaliteit van het product dat ik heb besteld.

We begrijpen je zorgen en we hanteren strenge normen voor kwaliteitscontroleen hoewel defecten uiterst zeldzaam zijn, is het een onvermijdelijke mogelijkheid.

Als er kwaliteitsproblemen optreden, nemen we de volledige verantwoordelijkheid en zullen we het reproductieproces tegen kostprijs versnellen.

We doen er alles aan om ervoor te zorgen dat onze producten voldoen aan de hoogste kwaliteitsnormen en om eventuele problemen direct aan te pakken zodat de klant tevreden is.

Neem contact op met

*Uw contact wordt niet gedeeld met derden.

Shenyang Vhandy Technology Co, Ltd.

Kamer 401, D11 Blok (Shenyang International Software Park), Shenyang, Liaoning, China

Telefoon/WeChat/WhatsApp

Tel

0086-24-31501218