In the realm of gas turbine engine manufacturing, the demand for materials with exceptional high-temperature stability and wear resistance is paramount. Different types of ceramics, such as 지르코니아, 알루미나, and mullite ceramics, have emerged as reliable choices for various engine components due to their remarkable properties.

Zirconia ceramics find various applications in gas turbine engines due to their exceptional properties. Some specific applications of zirconia ceramics in gas turbine engines include:

Thermal Barrier Coatings (TBCs):

Zirconia ceramics are widely used as the primary material for thermal barrier coatings in gas turbine engines. These coatings are applied to components such as turbine blades and vanes to protect them from high-temperature environments. Zirconia’s low thermal conductivity acts as an insulating layer, reducing heat transfer to the underlying metal substrate and allowing the engine to operate at higher temperatures.

노즐:

Zirconia ceramics are also employed in the manufacturing of nozzles used in gas turbine engines. Nozzles play a critical role in directing the flow of hot gases and ensuring efficient combustion. Zirconia’s high-temperature stability and wear resistance make it suitable for withstanding the harsh operating conditions and erosion caused by high-velocity gases and abrasive particles.

Combustion Liners and Flame Holders:

Zirconia ceramics can be utilized in combustion liners and flame holders within gas turbine engines. Combustion liners provide a controlled environment for fuel combustion, while flame holders stabilize and anchor the flame within the combustion chamber. Zirconia’s high-temperature stability and resistance to thermal shock make it an excellent choice for these components subjected to extreme heat and rapid temperature changes.

Spark Plugs:

Zirconia ceramics can be used in spark plugs for gas turbine engines. These spark plugs play a crucial role in igniting the fuel-air mixture in the combustion chamber. Zirconia’s electrical insulation properties and high-temperature stability make it suitable for withstanding the electrical and thermal stresses encountered during the ignition process.

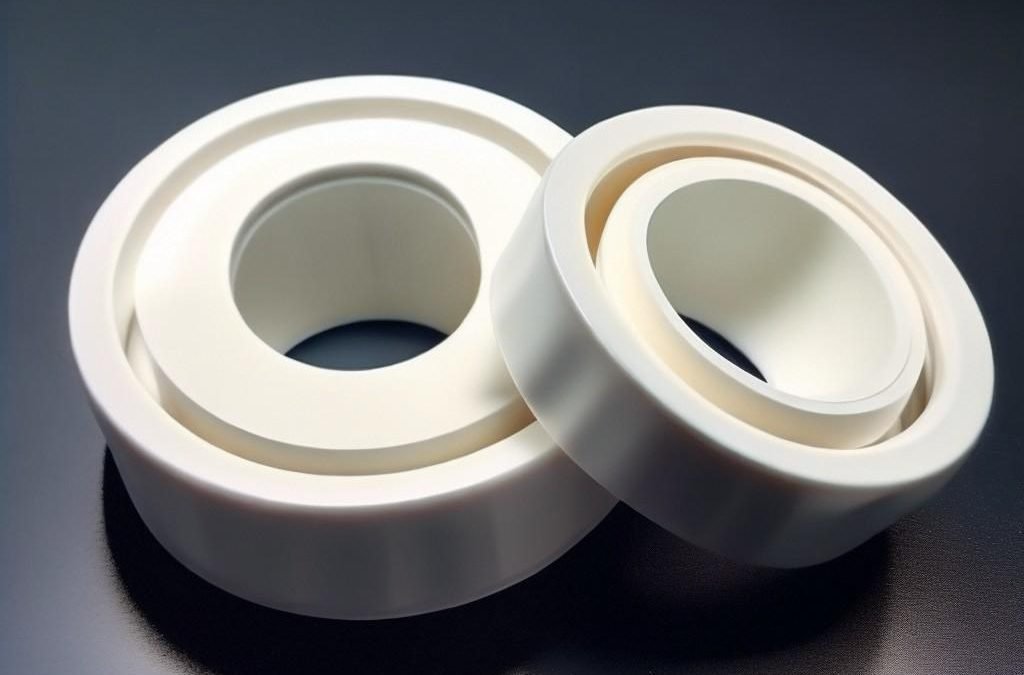

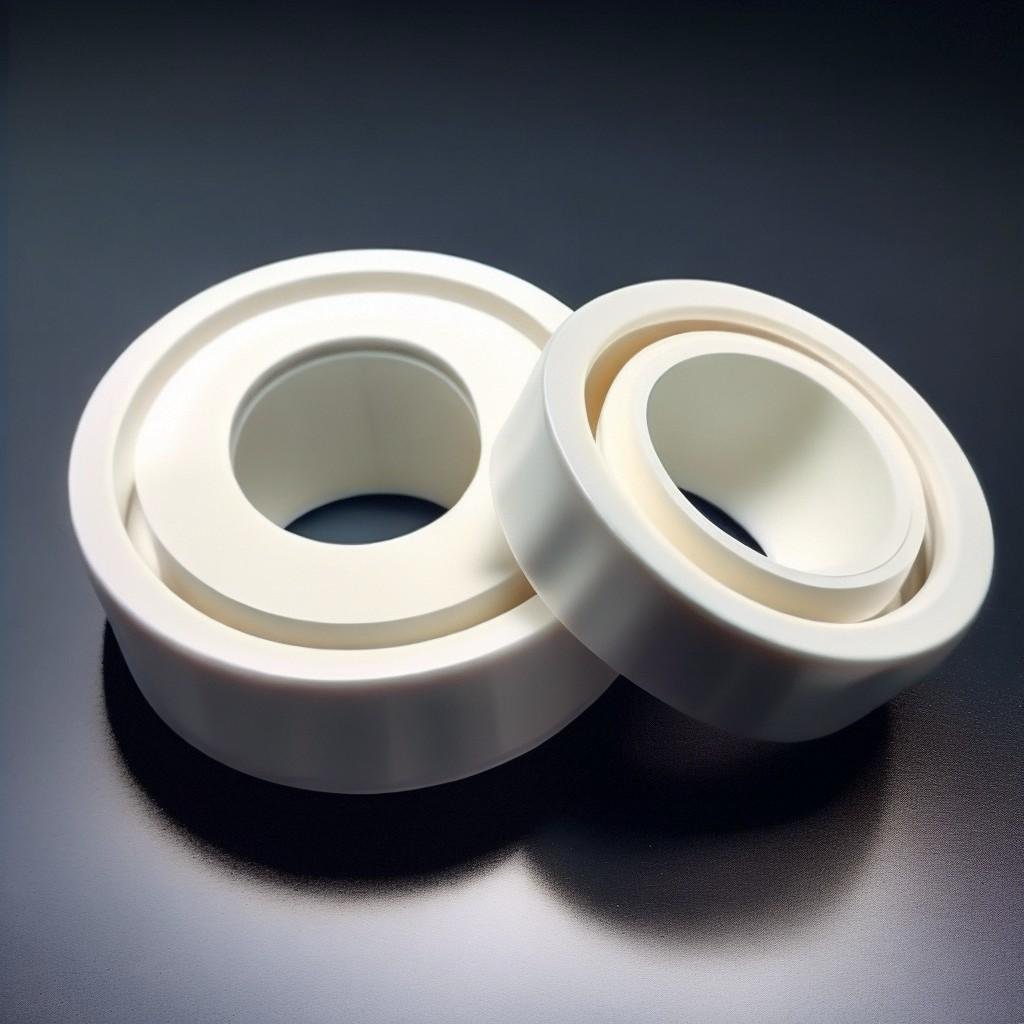

Bearings and Seals:

In certain gas turbine engine designs, zirconia ceramics can be employed in bearings and seals. Zirconia’s low coefficient of friction, excellent wear resistance, and high-temperature stability make it suitable for reducing friction and ensuring smooth operation between rotating components and stationary parts.

By leveraging the exceptional properties of zirconia ceramics, gas turbine engine manufacturers can enhance the performance, durability, and efficiency of their engines, ultimately leading to improved overall engine operation and reduced maintenance requirements.

At Vhandy Ceramics, we specialize in providing high-quality industrial ceramics that meet the stringent requirements of the gas turbine industry. Let’s compare the key properties of zirconia, alumina, and mullite ceramics in the table below:

| 속성 | 지르코니아 세라믹 | 알루미나 세라믹 | Mullite Ceramics |

|---|---|---|---|

| High-Temperature Stability | 우수 | 양호 | 우수 |

| 열 전도성 | Low | High | Low |

| 내마모성 | 우수 | 양호 | 우수 |

| Corrosion Resistance | Exceptional | 우수 | 우수 |

| 밀도 | High | High | Moderate |

Zirconia ceramics, known for their exceptional high-temperature stability and wear resistance, are widely used for manufacturing thermal barrier coatings and nozzles in gas turbine engines. They offer reliable performance even under extreme heat conditions, ensuring the longevity of engine components.

Alumina ceramics, on the other hand, exhibit good high-temperature stability and excellent corrosion resistance. They are commonly used for components that require high thermal conductivity, such as heat exchangers and insulators.

Mullite ceramics, with their excellent high-temperature stability, wear resistance, and corrosion resistance, are suitable for a wide range of gas turbine engine components. They offer a balance of properties that make them ideal for applications where both thermal and mechanical stresses are present.

As a leading industrial ceramics manufacturer, Vhandy Ceramics is committed to delivering products of the highest quality. Our advanced manufacturing techniques and stringent quality control processes ensure that our ceramics meet the industry’s most demanding standards. We work closely with our clients, understanding their specific needs, and providing customized solutions that optimize engine performance.

Partner with Vhandy Ceramics and experience the exceptional benefits of our high-quality ceramics for gas turbine engine manufacturing. Contact us today to discuss your requirements and witness the difference our expertise can make.

자주 묻는 질문

테스트할 수 있는 샘플을 제공해 주실 수 있나요? 비용은 얼마인가요?

저희는 최선을 다해 고객의 요구사항에 꼭 맞는 세라믹 샘플을 제공하기 위해 노력합니다.

The 샘플은 완전 무료입니다.하지만 운임을 지불해야 합니다.

맞춤형 금형이 필요한 독특한 모양의 샘플의 경우, 고객의 특정 요구 사항을 충족하기 위해 금형 비용에 대해 논의할 수 있습니다.

어떤 세라믹 소재가 필요한지 모르겠는데 어떻게 해야 하나요?

걱정하지 마세요! 사용 목적, 원하는 속성, 원하는 특정 특성 등 요구 사항에 대한 자세한 정보를 제공해 주세요.

이러한 정보를 바탕으로 고객의 니즈에 가장 적합한 세라믹 소재를 선택할 수 있도록 안내해 드립니다.

거래 조건은 어떻게 되나요?

조건은 EXW, FOB, CIF를 선호합니다.

T/T, 웨스트 유니온, 30% 보증금, 70% 배송 전 잔금 지불 를 보내주시면 대단히 감사하겠습니다.

세라믹의 처리 정확도는 어느 정도인가요?

| 정밀도 요구 사항 | 예제 | 단위 |

|---|---|---|

| 표면 평탄도 | Ra ≤ 0.1 μm | μm |

| 치수 정확도 | 수십 μm 이내의 허용 오차 | μm |

| 조리개 정밀도 | 수백 μm 이내의 직경 허용 오차 | μm |

| 표면 마감 | Ra ≤ 0.2 μm | μm |

엄격한 가공 정밀도 기준을 유지하여 표준 제조 공정을 통해 제품이 대부분의 요구 사항을 충족하도록 보장합니다.

하지만 더 높은 정밀도의 제품이 필요하다면 언제든지 문의해 주세요.

고객의 구체적인 요구 사항을 논의하고 고객의 엄격한 기준을 충족하는 맞춤형 솔루션을 모색할 수 있습니다.

주문한 제품의 품질이 걱정됩니다.

저희는 여러분의 걱정을 이해하며 엄격한 품질 관리 기준을 유지합니다.결함의 발생은 극히 드물지만 피할 수 없는 가능성입니다.

품질 문제가 발생하면 당사는 모든 책임을 지고 원가로 신속하게 재생산 절차를 진행합니다.

저희는 제품이 최고의 품질 기준을 충족하도록 보장하고 고객 만족을 보장하기 위해 모든 문제를 신속하게 해결하는 데 최선을 다하고 있습니다.

연락처

*연락처는 제3자와 공유되지 않습니다.

심양 브이핸디 테크놀로지 유한회사

401호, D11 블록(선양 국제 소프트웨어 파크), 선양, 랴오닝성, 중국

이메일

전화/위챗/왓츠앱

전화

0086-24-31501218