In the realm of gas turbine engine manufacturing, the demand for materials with exceptional high-temperature stability and wear resistance is paramount. Different types of ceramics, such as circonio, alúmina, and mullite ceramics, have emerged as reliable choices for various engine components due to their remarkable properties.

Zirconia ceramics find various applications in gas turbine engines due to their exceptional properties. Some specific applications of zirconia ceramics in gas turbine engines include:

Thermal Barrier Coatings (TBCs):

Zirconia ceramics are widely used as the primary material for thermal barrier coatings in gas turbine engines. These coatings are applied to components such as turbine blades and vanes to protect them from high-temperature environments. Zirconia’s low thermal conductivity acts as an insulating layer, reducing heat transfer to the underlying metal substrate and allowing the engine to operate at higher temperatures.

Zirconia ceramics are also employed in the manufacturing of nozzles used in gas turbine engines. Nozzles play a critical role in directing the flow of hot gases and ensuring efficient combustion. Zirconia’s high-temperature stability and wear resistance make it suitable for withstanding the harsh operating conditions and erosion caused by high-velocity gases and abrasive particles.

Combustion Liners and Flame Holders:

Zirconia ceramics can be utilized in combustion liners and flame holders within gas turbine engines. Combustion liners provide a controlled environment for fuel combustion, while flame holders stabilize and anchor the flame within the combustion chamber. Zirconia’s high-temperature stability and resistance to thermal shock make it an excellent choice for these components subjected to extreme heat and rapid temperature changes.

Spark Plugs:

Zirconia ceramics can be used in spark plugs for gas turbine engines. These spark plugs play a crucial role in igniting the fuel-air mixture in the combustion chamber. Zirconia’s electrical insulation properties and high-temperature stability make it suitable for withstanding the electrical and thermal stresses encountered during the ignition process.

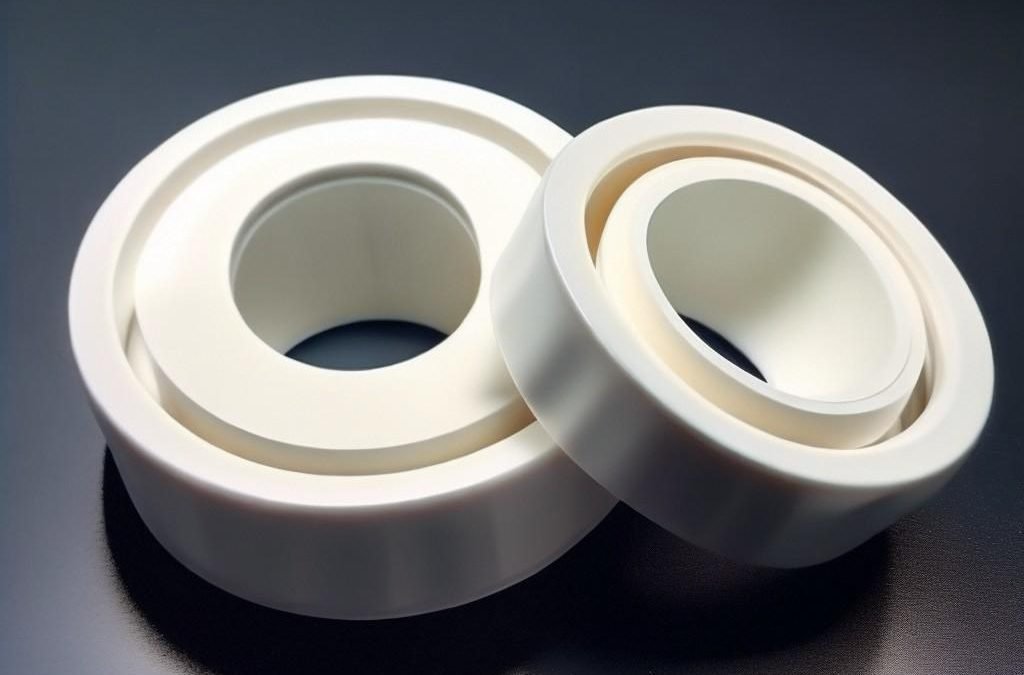

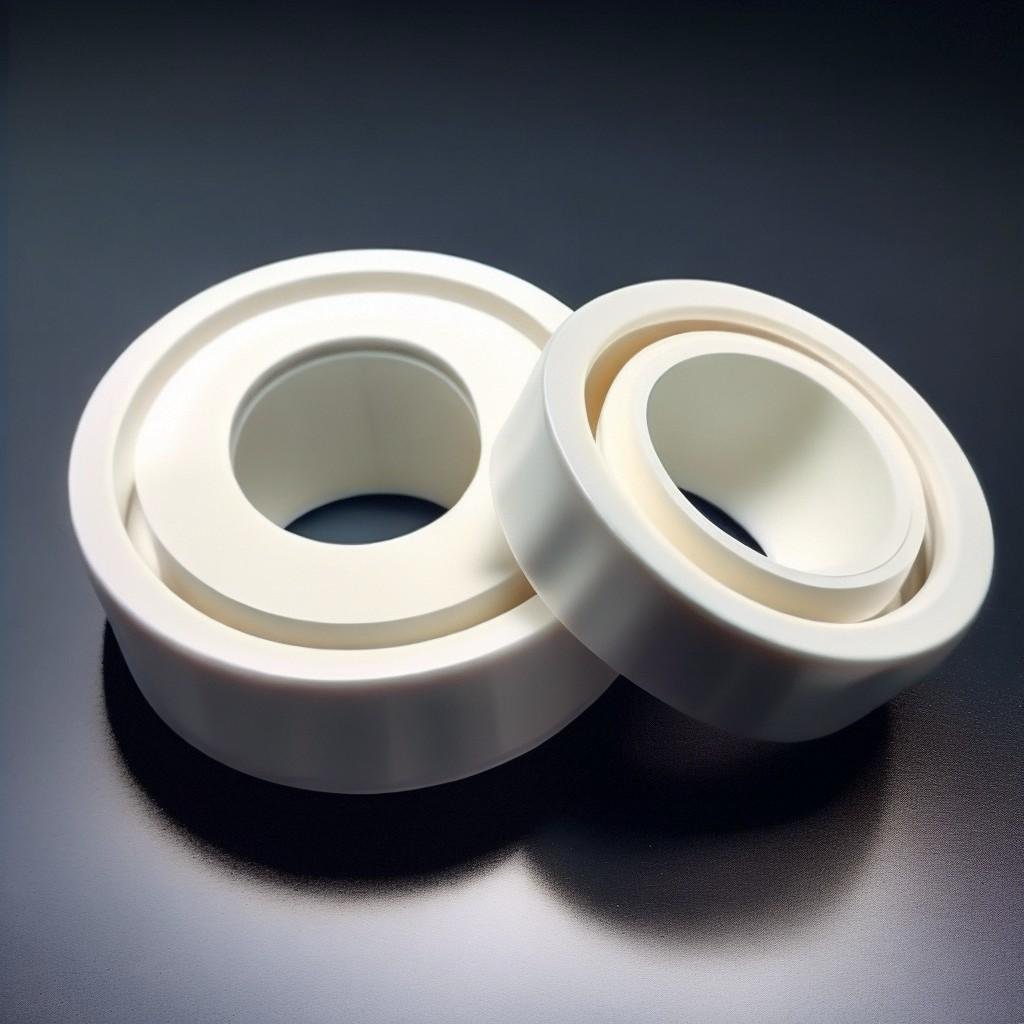

Bearings and Seals:

In certain gas turbine engine designs, zirconia ceramics can be employed in bearings and seals. Zirconia’s low coefficient of friction, excellent wear resistance, and high-temperature stability make it suitable for reducing friction and ensuring smooth operation between rotating components and stationary parts.

By leveraging the exceptional properties of zirconia ceramics, gas turbine engine manufacturers can enhance the performance, durability, and efficiency of their engines, ultimately leading to improved overall engine operation and reduced maintenance requirements.

At Vhandy Ceramics, we specialize in providing high-quality industrial ceramics that meet the stringent requirements of the gas turbine industry. Let’s compare the key properties of zirconia, alumina, and mullite ceramics in the table below:

| Propiedad | Cerámica de circonio | Cerámica de alúmina | Mullite Ceramics |

|---|---|---|---|

| High-Temperature Stability | Excellent | Good | Excellent |

| Conductividad térmica | Low | High | Low |

| Resistencia al desgaste | Outstanding | Good | Excellent |

| Corrosion Resistance | Exceptional | Excellent | Excellent |

| Densidad | High | High | Moderate |

Zirconia ceramics, known for their exceptional high-temperature stability and wear resistance, are widely used for manufacturing thermal barrier coatings and nozzles in gas turbine engines. They offer reliable performance even under extreme heat conditions, ensuring the longevity of engine components.

Alumina ceramics, on the other hand, exhibit good high-temperature stability and excellent corrosion resistance. They are commonly used for components that require high thermal conductivity, such as heat exchangers and insulators.

Mullite ceramics, with their excellent high-temperature stability, wear resistance, and corrosion resistance, are suitable for a wide range of gas turbine engine components. They offer a balance of properties that make them ideal for applications where both thermal and mechanical stresses are present.

As a leading industrial ceramics manufacturer, Vhandy Ceramics is committed to delivering products of the highest quality. Our advanced manufacturing techniques and stringent quality control processes ensure that our ceramics meet the industry’s most demanding standards. We work closely with our clients, understanding their specific needs, and providing customized solutions that optimize engine performance.

Partner with Vhandy Ceramics and experience the exceptional benefits of our high-quality ceramics for gas turbine engine manufacturing. Contact us today to discuss your requirements and witness the difference our expertise can make.

PREGUNTAS FRECUENTES

¿Pueden facilitarme muestras para que las pruebe? ¿Cuánto cuesta?

Nos esforzamos por proporcionarle muestras de cerámica que se ajusten lo mejor posible a sus requisitos.

En las muestras son totalmente gratuitaspero tienes que pagar el flete.

Para muestras con formas únicas que requieran moldes personalizados, estamos abiertos a discutir el coste del molde para adaptarnos a sus necesidades específicas.

No sé qué material de cerámica necesito, ¿qué debo hacer?

No se preocupe. Facilítenos más detalles sobre sus requisitos, como el uso previsto, las propiedades deseadas y cualquier característica específica que esté buscando.

Con esta información, nuestro equipo puede guiarle en la selección del material cerámico más adecuado a sus necesidades.

¿Cuáles son sus condiciones comerciales?

Preferimos EXW, FOB y CIF en cuanto a plazos.

T/T, West Union,30% depósito, 70% saldo pagado antes de la entrega son muy apreciadas.

¿Cuál es la precisión de procesamiento de la cerámica?

| Requisitos de precisión | Ejemplo | Unidad |

|---|---|---|

| Planitud de la superficie | Ra ≤ 0,1 μm | μm |

| Precisión dimensional | Tolerancia en decenas de μm | μm |

| Precisión de apertura | Tolerancia de diámetro dentro de unos cientos de μm | μm |

| Acabado superficial | Ra ≤ 0,2 μm | μm |

Mantenemos estrictas normas de precisión en el procesamiento, lo que garantiza que nuestros productos cumplen la mayoría de los requisitos mediante nuestros procesos de fabricación estándar.

No obstante, si necesita productos de mayor precisión, no dude en ponerse en contacto con nosotros.

Podemos hablar de sus requisitos específicos y estudiar soluciones personalizadas que cumplan sus normas más exigentes.

Me preocupa la calidad del producto que he pedido.

Comprendemos sus preocupaciones y mantenemos estrictas normas de control de calidady aunque la aparición de defectos es extremadamente rara, es una posibilidad inevitable.

Si surge algún problema de calidad, asumimos toda la responsabilidad y agilizaremos el proceso de reproducción a precio de coste.

Nuestro compromiso es garantizar que nuestros productos cumplen las normas de calidad más exigentes y resolver con prontitud cualquier duda para garantizar la satisfacción del cliente.

Póngase en contacto con

*Tus datos no se compartirán con terceros.

Shenyang Vhandy Technology Co., Ltd.

Sala 401, Bloque D11 (Parque Internacional de Software de Shenyang), Shenyang, Liaoning, China

Correo electrónico

Teléfono/WeChat/WhatsApp

Tel

0086-24-31501218