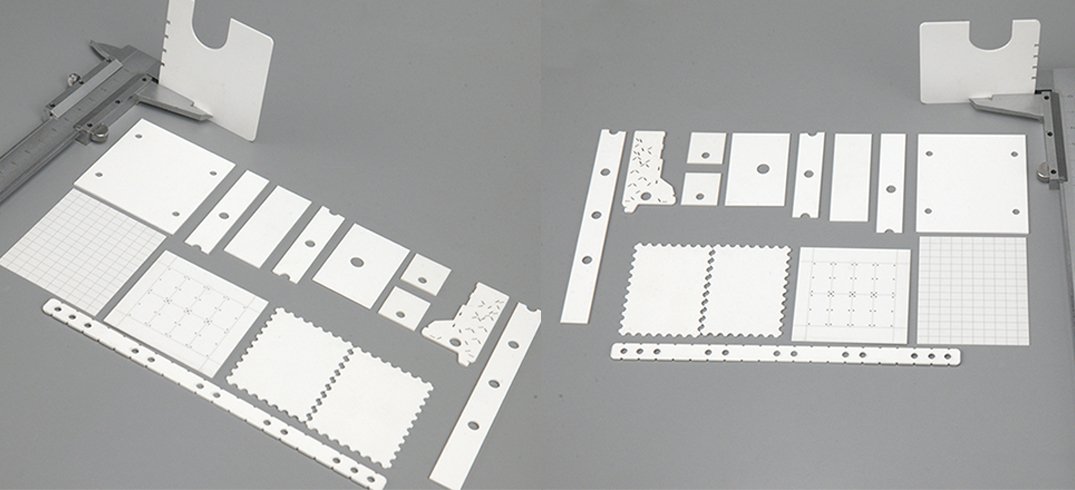

There are many thickness specifications and sizes of wear-resistant ceramic linings. There are three main types that are often used: 10*10, 17.5*17.5, and 20*20. The thinnest is 3mm and the thickest is 20mm. Generally, the appropriate size is selected according to your own construction conditions, which can prevent wear and not waste materials.

Wear-resistant ceramic linings are made of alumina or zirconium oxide by high-temperature calcination. Alumina is converted into dense alpha alumina under high temperature. Due to its special crystal structure, it becomes extremely hard and its hardness is second only to diamond. The wear resistance is several times or even more than that of other wear-resistant materials. In addition, due to the smooth surface of the wear-resistant ceramic lining, the surface resistance is very small, which is also an important reason for greatly improving its wear resistance.

Characteristics of wear-resistant ceramic linings

High hardness: The Rockwell hardness of the wear-resistant ceramic lining is above HRA90, which is second only to diamond, far exceeding the wear resistance of wear-resistant steel and stainless steel. Excellent wear resistance: Its wear resistance is equivalent to 30 times that of manganese steel and 20 times that of high chromium cast iron. According to customer follow-up surveys over the past 20 years, under the same working conditions, it can extend the service life of the equipment by at least ten times. Lightweight: Its density is about 3.6g/cm³, which is only half of that of steel, which can greatly reduce the load on the equipment.

If you need, please feel free to contact us 0086-17702411651